In PCB design, understanding the intricacies of integrating a DC 5V input is crucial for ensuring stable and efficient power delivery across the board. This article explores how a DC 5V power supply takes a standard 220V AC input and converts it to a regulated 5V DC output.

IPC class definitions in electronics manufacturing categorize PCBs into three classes, ranging from Class 1 (basic quality) to Class 3 (highest quality). These classifications determine the level of reliability and performance required for various electronic products, impacting their overall quality and suitability for different applications. Understanding these classes helps manufacturers ensure their products meet the necessary standards and perform reliably in their intended use.

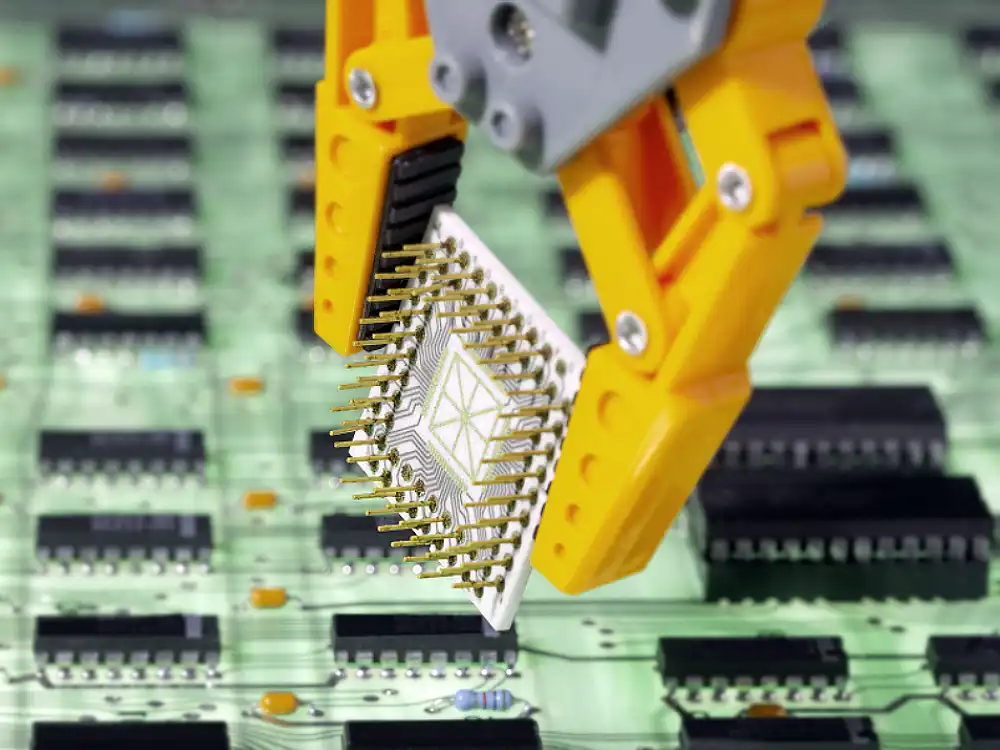

SMT lines (surface mount technology) involve the process of mounting electronic components onto printed circuit boards (PCBs). This article explores the differences between automated and manual SMT lines, and their role in PCB assembly and testing in modern electronics manufacturing. Learn about the key components and processes that drive these high-tech systems.

We explore the leading players in the Electronics Manufacturing Services (EMS) industry. The list highlights companies excelling in innovation, quality, and market reach. We delve into their achievements, market strategies, and contributions to the global electronics sector. From established giants to emerging contenders, this comprehensive overview provides insights into the top EMS companies shaping the future of electronics manufacturing in 2024.

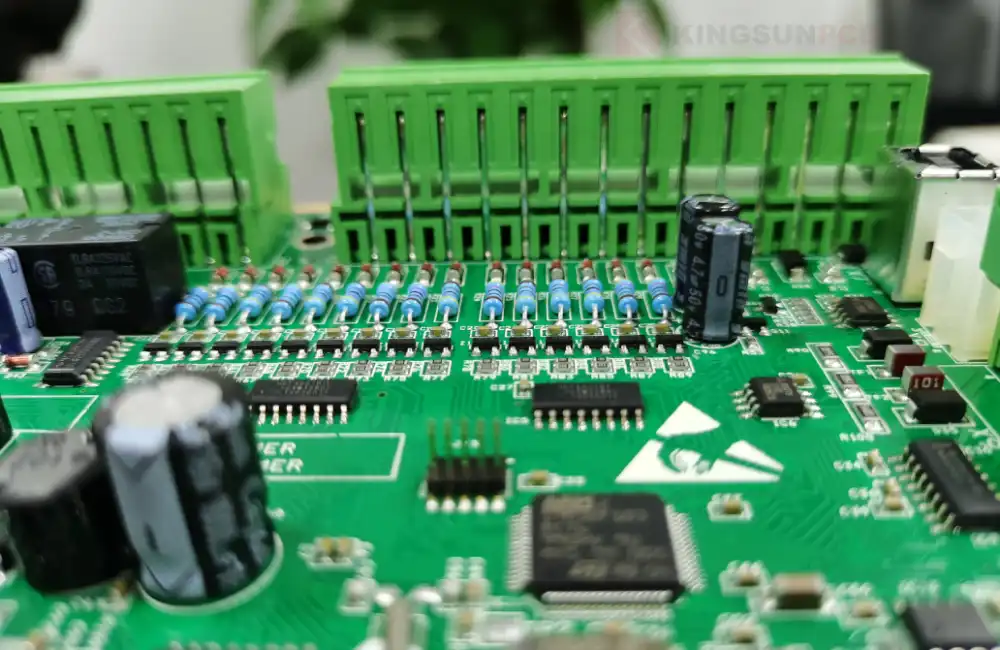

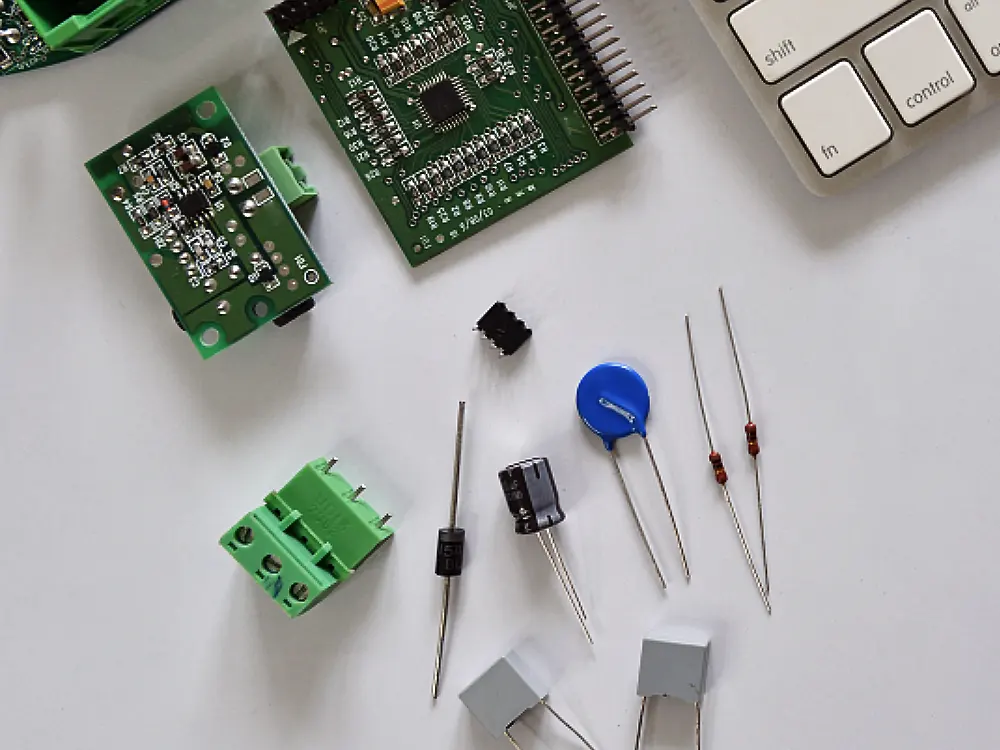

The topic explores the components comprising a circuit board. It delves into the fundamental elements essential for constructing circuits, ranging from resistors to capacitors and beyond. By understanding the roles and functions of each component, individuals can grasp the intricacies of circuitry and its applications.

A comprehensive guide to vias in electronic printed circuit boards (PCBs). This article details the definition and role of vias, explains its importance in PCB design, and common usage scenarios. You will learn about the different types of vias and their uses, as well as how to apply them in the PCB manufacturing process.

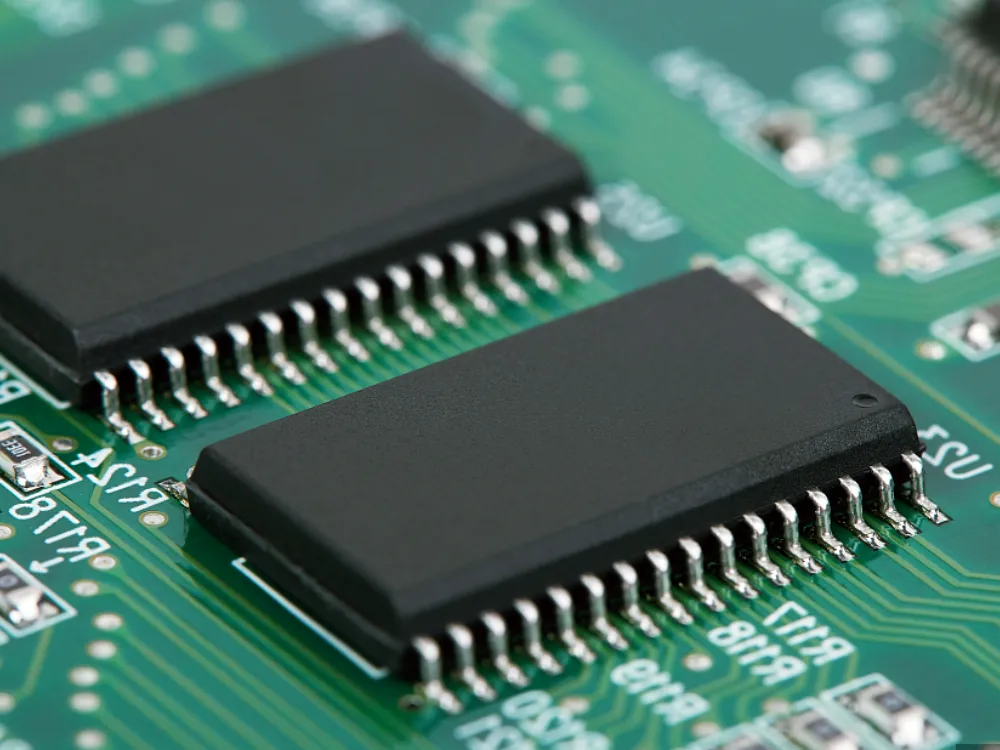

DIP refers to an electronic component package. It has two rows of pins for connection. DIPs are common for ICs like microprocessors and memory chips. They are known for their easy handling and secure connections. But, they are larger than surface-mount packages. Variants include Zig-zag DIP (ZIP) and Shrink DIP (SDIP), each with unique characteristics.

When you are working with wire soldering, there are often times when you need to remove excess solder. At this point, the wire desoldering magnet or solder pump may not be of use, and this is where wire soldering comes in. This article introduces in detail the meaning and function of solder wire, as well as how to select and use it.

How are PCBs manufactured? It is one of the exciting questions PCB hobbyists ask. The process of manufacturing PCB boards is lengthy and complicated. Its manufacturing process involves multiple steps. The circuit board can cause performance issues if we do not follow the correct method. PCB development requires expertise from beginning to end. It mainly depends…

Introduction: Chip On Board (COB) technology has reached a state of stability within the electronics manufacturing sector. In the past, people used COB to produce less expensive consumption goods. COB is more suitable than IC for use in confined spaces as electronic devices continue to shrink in size. In this post, we will discuss chip-on-board…