Introducción

Certainly, diseño de PCB is critical to ensure that the electronic components are connected fittingly.

In PCB design, DC 5V input is a pivotal aspect. It ensures a compatible, stable, and regulated voltage for your electronic endeavors or projects.

This article will shed light on what DC 5V input is. What are the main factors that impact DC 5V requirements?

You’ll learn about important principles when designing PCBs for DC 5V input. You’ll also learn how to create a DC 5V power supply on PCB.

Keep reading to understand all the key aspects of 5V DC input in detail.

What is DC 5V Input?

DC 5V input is a direct current (DC) voltage of 5 volts of the power supply. It’s used broadly by the following:

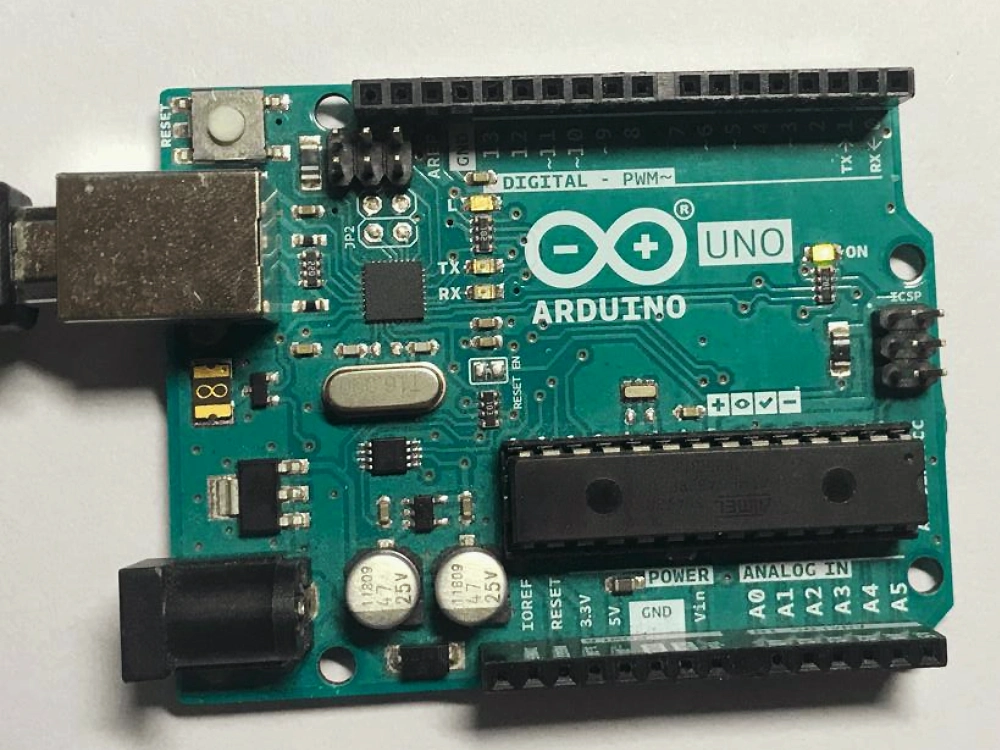

- Electronic projects and devices akin to microcontroller-based systems, e.g. Raspberry Pi and Arduino

- LED lighting systems

- Sensors like proximity sensors or temperature sensors

These devices and projects need a stable, regulated direct current input of 5 volts. Only then will their components work reliably, resulting in optimal performance.

Thus, correct voltage regulation is necessary for the accurate function of these devices and systems.

Factors Influencing DC 5V Input Requirements

The following are some factors that impact 5V input needs in PCB design:

1. Voltage Specifications of Components

You may know that there are different components used in electronic projects. These include sensors, microcontrollers and Integrated Circuits (ICs). These components have particular voltage requirements.

In PCB design, the voltage specifications of components must be considered. The goal is the correct and efficient functioning of the circuit.

2. Conversion and Regulation Techniques

Different components may need different voltage specifications. Thus, it’s crucial to use conversion and regulation procedures and techniques. They ensure that the components acquire a stable 5V input and function steadily.

3. Power Supply Efficiency

Power supply efficiency has a clear effect on the 5V DC input stability.

If the efficiency is high, it greatly reduces voltage fluctuations. It also assures reliable and smooth working in various electronic projects.

Designing PCBs for DC 5V Input Compatibility

When designing PCBs for DC 5V input compatibility, some factors must be remembered. These are as follows:

1. Component Selection

Component selection is a crucial factor in PCB design for 5V DC input.

The components must be rated for the appropriate voltage range. Namely, transistors, Integrated Circuits (ICs), and other active electronic components must have appropriate voltage tolerances. The purpose is their smooth handling of the DC 5V input and steady operation.

2. Component Placement

In PCB design for 5V DC input compatibility, the placement of electronic components is crucial.

Significantly, the components should be placed in a way that reduces possible noise. It should also raise operating efficiency and heat dissipation.

To achieve this aim, you must

- Group components as per their functions

- Place high-frequency electronic components near the power source.

- Place decoupling capacitors near the power source to reduce noise and ensure voltage stability.

- Place heat-emitting components at a distance from sensitive components

- Make sure the traces are short as far as possible

Noise means the unwanted signals that interfere with the specific signals that a circuit processes. Apart from this, it’s also necessary to ensure thermal management and heat dissipation. The motive is to avoid overheating and voltage fluctuation.

3. Trace Routing

Trace routing in PCB design is a critical process. It connects components on a PCB via copper traces. It can essentially impact the reliability and performance of the circuit.

The aim is to reduce noise and interference as far as possible.

When routing traces for 5V DC input, you must:

- Keep traces short as far as possible to lessen resistance and drop in voltage.

- Use comparatively wider traces for high-current requiring components to lessen heat generation.

- Prevent crossing traces to reduce noise and interference

- Utilize ground planes and power planes. They reduce noise and maintain a consistent voltage supply across the PCB.

Testing and Validating DC 5V Input

It’s extremely necessary to test and validate 5V DC input. It is to ensure that the circuit functions efficiently and correctly.

Multimeters and oscilloscopes are essential tools that measure voltage levels and assess stability. A multimeter gives an accurate reading of current, voltage and capacity in number format. But, an oscilloscope shows a waveform of voltage signal on its screen to measure voltage.

They help ensure the DC 5V input remains stable under varied working conditions.

Performing Stress Tests and Checking Power Efficiency

It’s also essential to perform stress tests. They aid in assessing the PCB performance under varied load conditions. Further, they help check the 5V DC input’s consistency and reliability.

PCB designers should also check aspects like the consumption and efficiency of power. The goal is to identify any issues regarding the 5V DC input’s consistency. It can be done by determining the current drawn by the circuit.

How to Create a 5V Power Supply on PCB

The following are the vital steps for creating a 5V Power Supply on PCB:

1. Determine the Power Requirements

The first step is to determine the circuit’s power requirements correctly. To this end, calculate the total current needed by adding the current needs of all components in the circuit.

The power supply should give adequate current to meet the circuit requirements.

You must also choose components that can handle and operate with that load. Remember any potential current spikes that could occur while the circuit is working.

2. Select a Power Supply IC

Next, choose an appropriate SMPS (switch-mode power supply) IC or voltage regulator. It deals with the desirable input voltage and gives a stable 5V output. An example of a voltage regulator that can be used is LM7805.

You must ensure that the voltage regulator is correctly heatsinked. The goal is to avert overheating.

3. Design the Power Supply Circuit

The next and most critical step is designing the power supply circuit. For this, adhere to the datasheet and instructions of the chosen IC or voltage regulator.

It would be best if you took notice of the following factors:

- Component placement

- Trace routing

- Decoupling capacitor placement

The objective is to give out optimal operation of the circuit.

Decoupling capacitors filter out noise and voltage spikes that can break the circuit. They should be placed near the power pins of the components for which they are protective.

This strategic placement of the decoupling capacitors has a purpose. It aids in lessening the length of the traces between the components and the capacitor. It reduces the circuit inductance and makes the capacitor effective and reliable.

4. Incorporate Input Voltage Protection

You read about the previous step of designing the power supply circuit earlier. The next step is to incorporate input voltage protection methods. The goal is to safeguard the circuit from potential input voltage problems.

For this purpose, reverse polarity protection diodes or fuses can be used. Such diodes and fuses protect if the power supply polarity is reversed. It can prevent permanent damage to the circuit or a risk of fire.

5. Test and Verify

Lastly, complete testing of the PCB’s 5V DC power supply circuit. The following are the aims for this step:

- Ensure that the circuit remains stable under varied load conditions

- Ensure that it provides the desirable output voltage

- Ensure it meets all the other needed specifications

Real-World Applications

5V DC input finds applications in microcontroller-based systems, low-powered devices, and sensors.

The 5V input is used to power the microcontroller and its components. Furthermore, sensors like proximity or temperature sensors operate on 5V DC input.

Additionally, low-powered devices like IoT or portable electronic devices use 5V DC input.

Yet, such real-world applications also raise issues about voltage compatibility and regulation.

Among such issues, noise interference can affect 5V DC input. It can lead to unpredictable behavior or electronic devices or systems breaking down. To help address them, adhere to approaches like:

- shielding techniques

- appropriate grounding

Thus, engineers can ensure that the 5V DC input-powered electronic systems work reliably.

Conclusión

You should have had ample understanding of 5V DC input in PCB design by now.

To conclude, factors like voltage specification of components and conversion and regulation techniques should be considered. They help ensure a stable DC 5V input in the long run.

You also learned the procedure to create a DC 5V power supply on PCB. Lastly, we also shed light on real-world applications and uses of DC 5V input.

Follow the best practices and guidelines we provided in this article. It assures the reliability and safety of the electronic systems relying on 5V input.

King Sun PCB: Your DC 5V Input PCB Manufacturing Partner

When making PCBs for 5V DC input, King Sun PCB is your ideal manufacturing partner.

We specialize in rapid turnaround prototyping and low-volume Printed Circuit Board design and manufacturing. We also provide top-tier and competent Servicios de montaje de PCB based in Shenzhen, China.

You can bank on King Sun PCB’s services for ideal PCB designs. Our PCB design assessment procedures ensure stable 5V input compatibility. Any issues in PCB design that may be present are detected and eliminated early. We can also install components on your PCBs via our assembly services. It also includes voltage regulators to produce the 5V input power supply.

We deal with a vast range of PCB products and have rich manufacturing experience. Our team of highly skilled engineers ensures quick delivery and exceptional standards of PCB products.