What is HDI PCB?

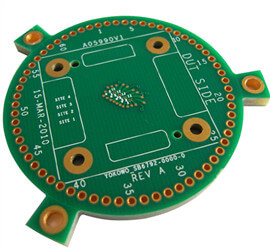

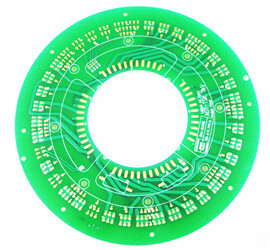

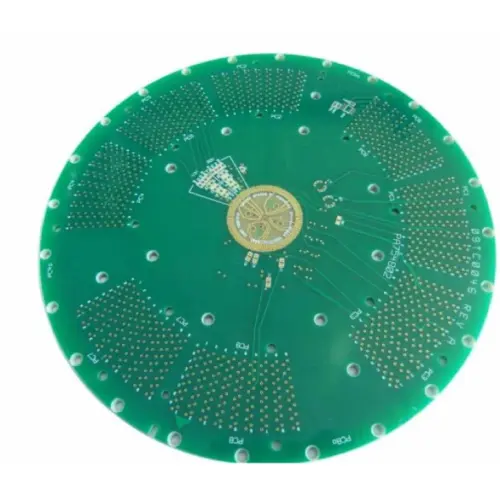

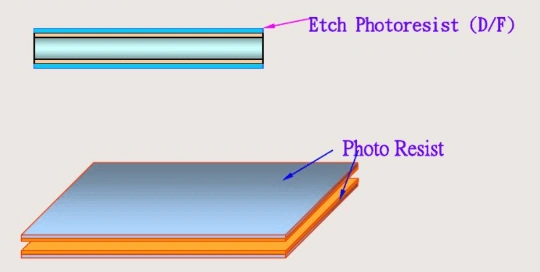

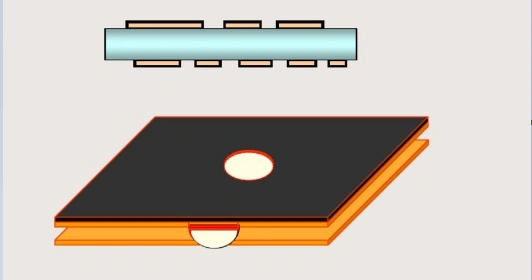

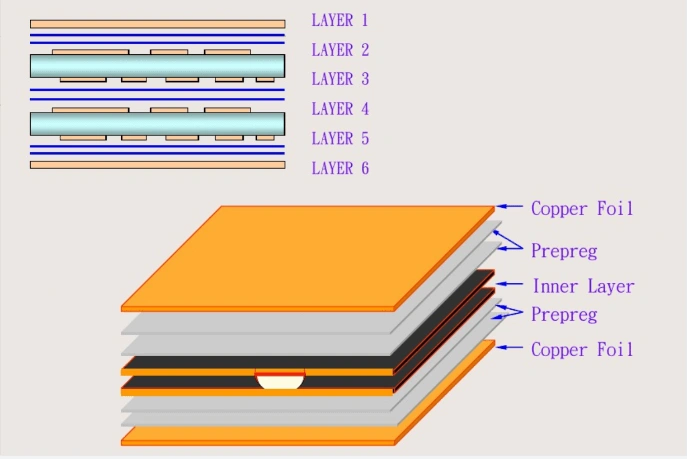

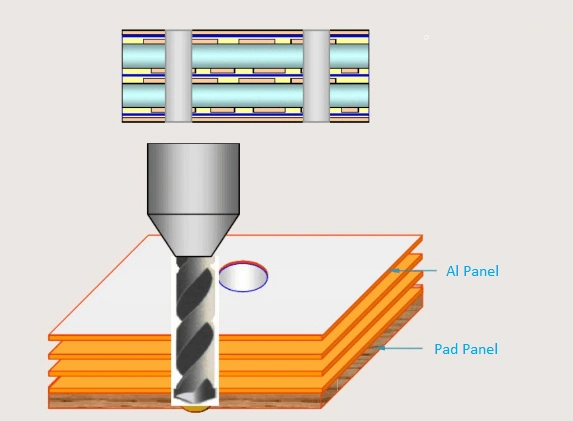

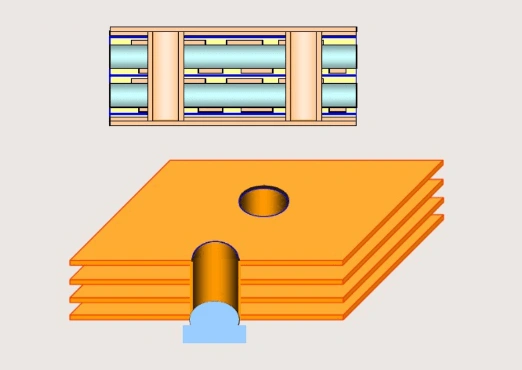

HDI PCB is the abbreviation of high density interconnector PCB. HDI PCB manufacturer makes the HDI board by increased layers through micro-blind&buried vias.

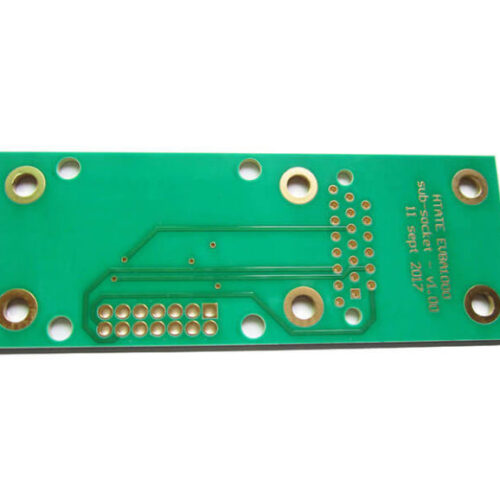

HDI PCB board is a compact product specially designed for small capacity users.

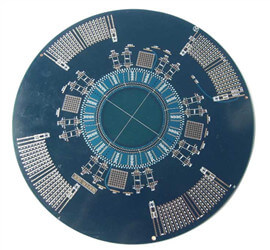

The HDI board includes the following via types:

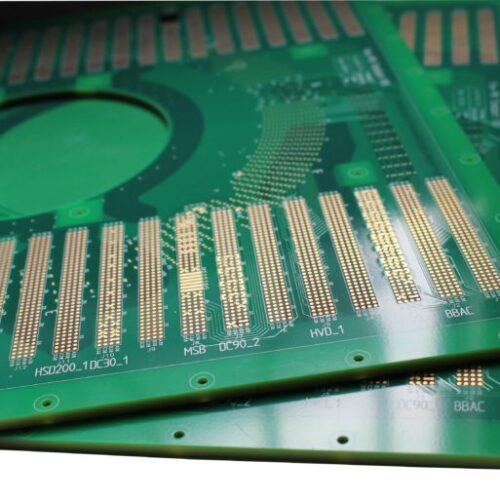

PCB de microvía: en la industria de PCB, las vías con un diámetro inferior a 150 um (6 mil) se denominan microvías.

Vías enterradas: Las vías están enterradas en la capa interna, generalmente no visibles en el producto terminado.

Blind vias: The blind vias are drills from top layer or bottom layer to a certain inner layer. They are not through the whole HDI board.