MCPCB 보드의 유형

Classify by layer counts

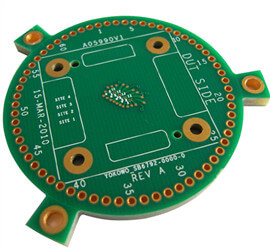

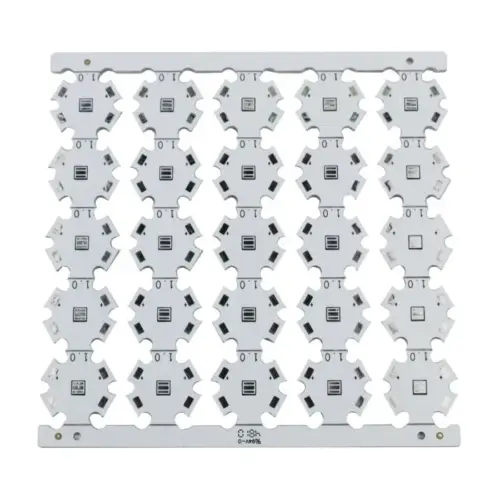

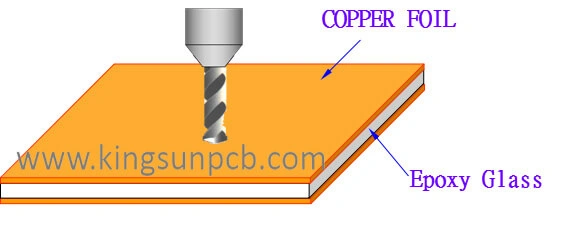

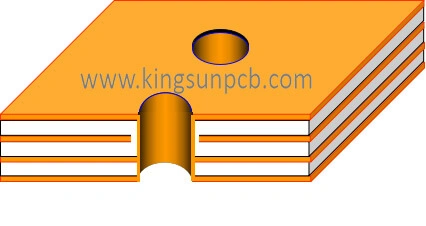

Single Sided MCPCB Board

Single sided MCPCB board is the most common type. Compared with other types of metal core PCB board, its process is simple and its application is particularly extensive, often used in LED lighting products. It consists of three parts: the copper foil, the insulating layer and the metal-clad layer.

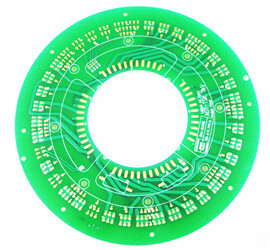

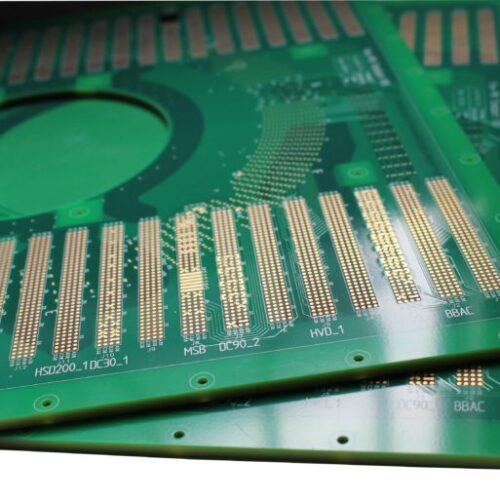

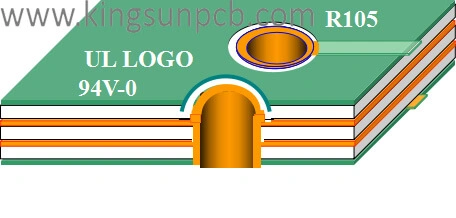

2레이어 MCPCB 보드

2 Layer MCPCB board can layout components on both sides. The structure is relatively complex and consists of five structures: The circuit layer, the dielectric layer, the aluminum-clad layer, the dielectric layer, and the circuit layer. There are more resin filling processes and plating processes in MCPCB fabrication, which require twice drillings.

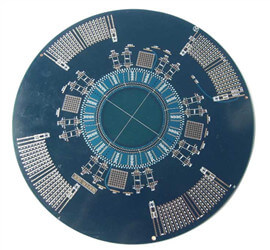

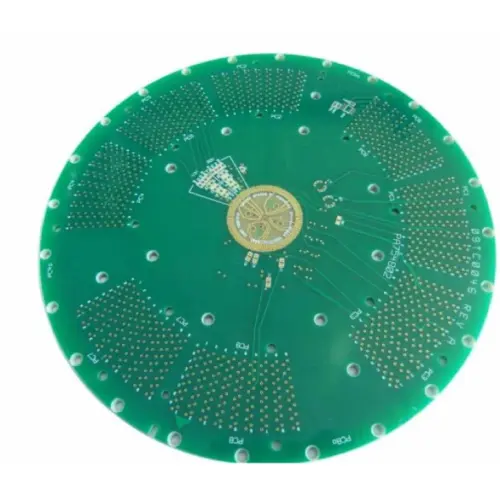

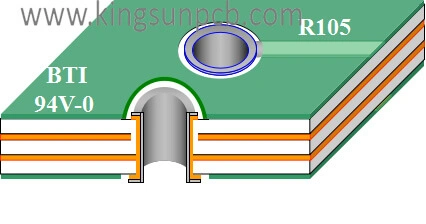

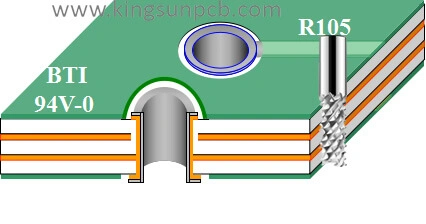

다층 MCPCB 보드

In the high-performance power supply industry, multilayer MCPCB board are made of multilayer thermally conductive dielectrics. These structures have one or more layers of circuitry buried in a dielectric, with blind vias used as thermal vias or signal paths.

재료별로 분류

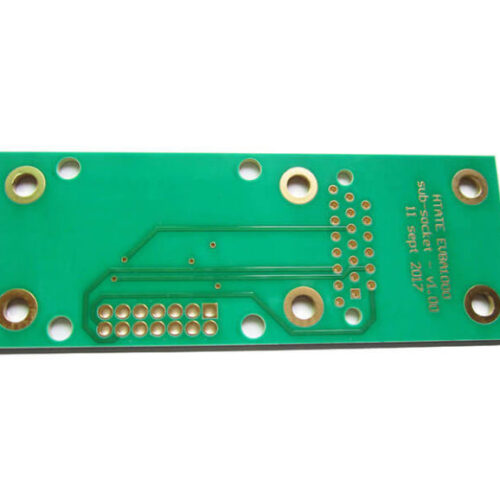

유연한 MCPCB 보드

One of the latest developments in metal core PCB is the flexible dielectric. These materials provide excellent electrical insulation, flexibility and thermal conductivity. When applied to flexible MCPCB board, the product can be realized in various shapes and angles, and can be bent without cracking. Cost savings on expensive fixtures, cables and connectors.

구리 코어 PCB

Copper Core PCB is copper metal core PCB, The heat dissipation of the copper core PCB is very good, and it is suitable for high-frequency circuits, as well as heat dissipation of precision communication equipment and architectural industries.

철심 PCB

Iron Core PCB metal clad layer is iron. The hardness of the iron substrate is much greater than the manufacturing process and difficulty of the aluminum substrate, It’s used in high-end motors, high-end product equipment and motors.