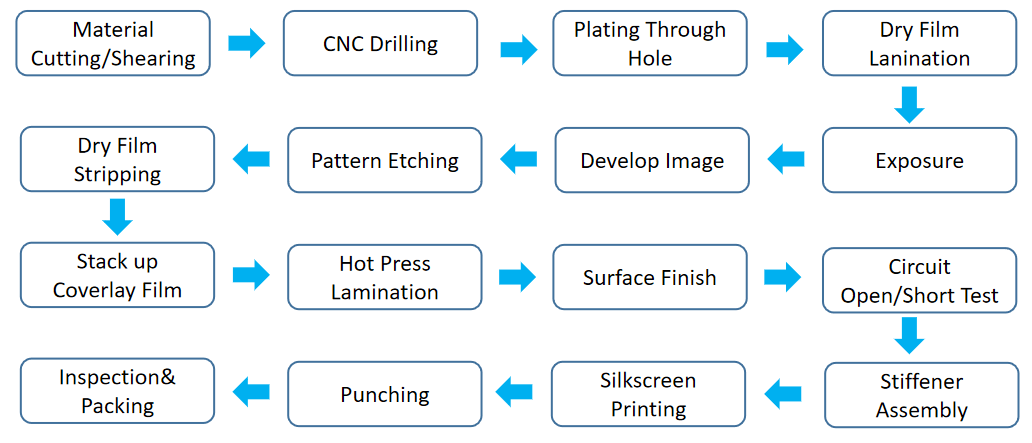

Materialschneiden/-scheren

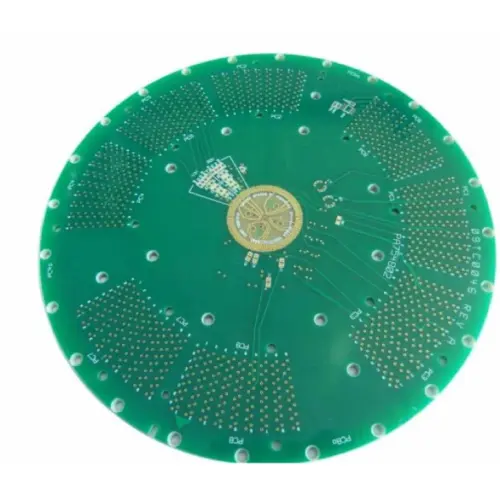

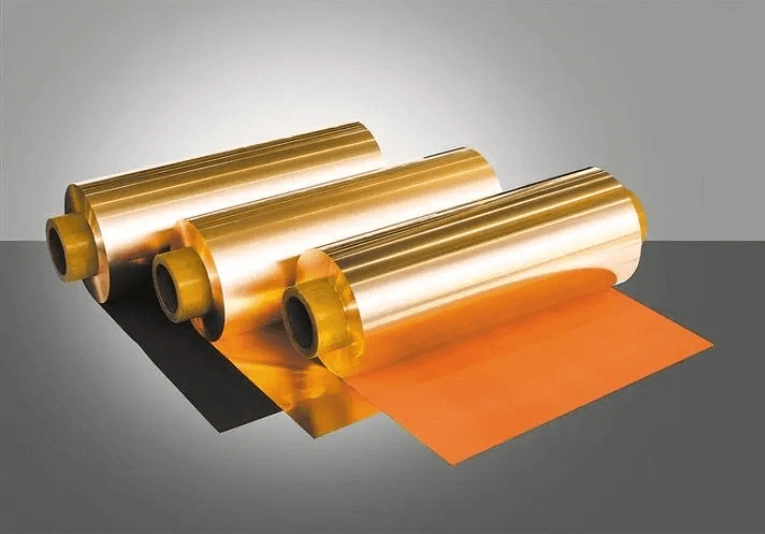

The flexible printed circuit board material is generally a roll of 250mm wide 50M or 100M long PI base material covered with a certain thickness of copper on one or both sides of the copper foil. Therefore, we need to cut the large roll into a work board according to the size of the manufacturer’s instructions.

CNC-Bohren von flexiblen Leiterplatten

Das Bohren ist der zweite Schritt im Herstellungsprozess flexibler Leiterplatten, und die Qualität des Bohrens steht in direktem Zusammenhang mit der Funktion und Genauigkeit des Produkts.

Along with the continuous development of high-density flexible PCB, Traditional mechanical drilling technology can no longer meet the market demand for small hole diameter, high precision and high efficiency. Laser drilling has become the mainstream processing technology for flexible PCB microvias.

Durchkontaktierung

VCP electroplating line using Faraday’s theorem (the thickness of the coating is proportional to the current density and plating time) to plat the hole wall of the flexible printed circuit board to copper thickness following IPC standard or required by customer.

Trockenfilm-Laminierung

Composed of PE, photoresist and PET, paste dry film on the flexible printed circuit board, so as to achieve the function of image transfer, and protect the circuit during the etching process.

Belichtung

Entsprechend der dem Arbeitsauftrag entsprechenden Filmbelichtung wird das Bild des flexiblen gedruckten Schaltungsgrafikfilms auf den Trockenfilm übertragen (fertiggestellt in der staubfreien Werkstatt auf Ebene 10.000) und die Hauptausrüstung ist eine automatische Belichtungsmaschine.

Bild entwickeln

The part of the dry film that is not exposed to light will be washed off by NaCO3, and the dry film on the trace and copper will not be washed off. Useful wiring and copper of flexible printed circuit board are preserved

Musterätzen

Beim Ätzen flexibler Leiterplatten wird unerwünschtes Kupfer von einer Leiterplatte entfernt.

Etching has acid etching process (ferric chloride and copper chloride) and alkaline etching process (ammonia). The acid method is used to etch the inner layers of flexible printed circuit board, it is accurate and cheap but time consuming. The alkaline method is used to etch the outer layer of the flexible PCB, which is fast and expensive.

Trockenfilm-Stripping

Flexible printed circuit board dry film stripping removes the protective dry film layer on the FPC circuit board through a chemical reaction. This process is usually done using chemical solutions, which can decompose the chemical substances in the film layer and expose the flex printed circuit board.

Bei der Entwicklungs- und Ätzfilmentfernungsanlage handelt es sich um eine horizontale DES-Linie.

Stapeln Sie das Flex-PCB-Coverlay

Flexible printed circuit board coverlay film, generally also called protective film, protects the circuit from oxidation and covers it for subsequent surface treatment. If the area that does not need gold plating is covered with coverlay. In the subsequent SMT soldering, the role of prevent welding.

Heißpress-Laminierung

Durch Pressen bei hoher Temperatur und hohem Druck, gefolgt von Backen bei hoher Hitze, wird der wärmehärtende Klebstoff zwischen der Deckfolie und der Platte ausgehärtet, um den Zweck der festen Verbindung der beiden zu erreichen. Die Aushärtungsarbeitsparameter sind eine Temperatur von 150 ° C, 1 Stunde. Die Hauptausrüstung sind Schnellpressen und Öfen;

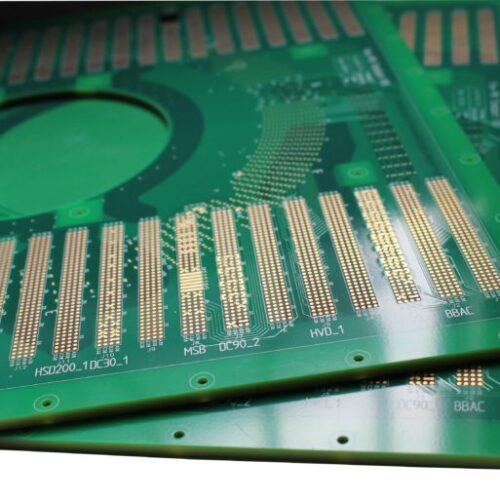

Oberflächenbeschaffenheit flexibler Leiterplatten

Die Oberflächenbehandlung flexibler Leiterplatten erfolgt hauptsächlich durch Tauchgold oder ENEPIG. Je nach Kundenwunsch werden Metalle wie Nickel und Gold mithilfe chemischer oder galvanischer Verfahren auf die freiliegenden Pads flexibler Leiterplatten aufgebracht, um die Pads zu schützen und ihre Lötbarkeit zu erhalten. Die Hauptausrüstung besteht aus vergoldeten Leitungen und vergoldeten Leitungen.

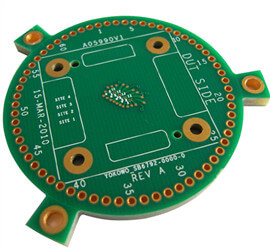

Prüfung auf Unterbrechung/Kurzschluss flexibler Schaltkreise

Check whether there are open and short circuits between different networks of the flexible printed circuit board, four-wire failure, etc. through test fixtures or equipment. The main equipment is an electric test machine and a flying probe test machine;

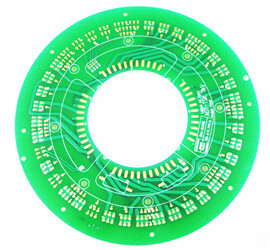

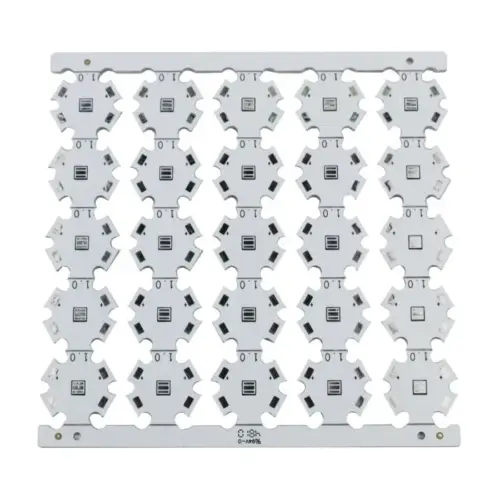

Flexible PCB-Versteifungsbaugruppe

Der Zweck des Aufklebens eines Flex-PCB-Versteifungselements besteht darin, die mechanische Festigkeit der flexiblen Leiterplatte zu erhöhen und die Montage von Teilen auf der Oberfläche der Leiterplatte zu erleichtern.

Zu den FPC-Versteifungsmaterialien gehören gängige Polyimid-Versteifungen, FR4-Versteifungen und Stahlversteifungen.

FR4 stiffener main components are glass fiber cloth and epoxy resin glue, which is the same as the FR4 material used in PCB.

Steel stiffener is made of steel, which has strong hardness and support strength. Manual assembly is required, the process is more complicated, and the cost will be higher.

PI stiffener is as same as the coverlay film, consisting of PI and adhesive release paper, but the PI layer is thicker, can be processed and produced from 0.05mm to 0.25mm, the tolerance can be controlled at +/- 0.03mm, and the precision is high , high temperature resistance (100°C-280°C).

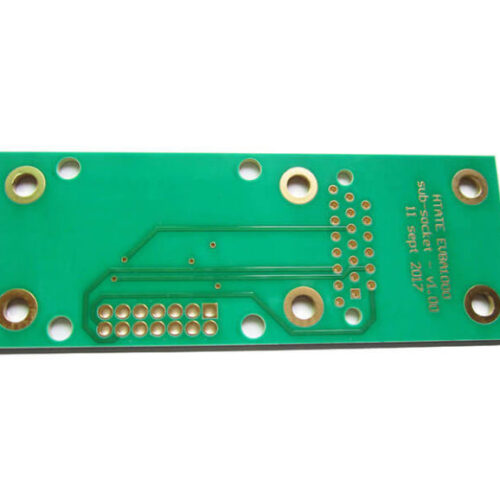

Siebdruck

Print the text ink on the flexible printed circuit board through the principle of screen printing, mainly printing the product model, production date code, and various component identifications required by customers, etc. The main equipment includes screen printing machines, ovens, text inkjet printers, etc.;

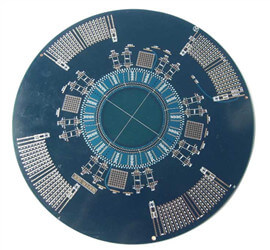

Flexibles Stanzen von Leiterplatten

Flexible printed circuit board punching is a link in the FPC process, which is equivalent to a cutting workstation. At present, the main equipment used in this workstation on the market is flex circuit punching machine and FPC UV laser cutting machine.

Das Prinzip der Stanzmaschine für flexible Leiterplatten besteht darin, durch den Zylinder Druck auszuüben, um die Messerform in den Träger zu drücken und so das Schneiden der flexiblen Schaltung in einem Schritt durchzuführen.

Das Prinzip der Laserschneidmaschine für flexible Leiterplatten besteht darin, die Oberfläche der FPC mit einem energiereichen und hochdichten Laserstrahl zu bestrahlen und ihn durch den vibrierenden Spiegel hin und her zu bewegen, um eine Schnittschicht aus Glasmaterial zu bilden.

Inspektion und Verpackung

Durch manuelle Sichtprüfung und CCD-Geräte können das Aussehen und der Oberflächenzustand der flexiblen Leiterplatte vollständig überprüft, gute von fehlerhaften Produkten getrennt und Zuverlässigkeitstests am Produkt durchgeführt werden, um zu bestätigen, ob es die Kundenanforderungen erfüllt.

Packaging and shipping flex circuits are carried out according to customer requirements. The main packaging methods include vacuum packaging, micro-membrane packaging, tray packaging, etc.