Rigid And Flex PCB Materials Are Different

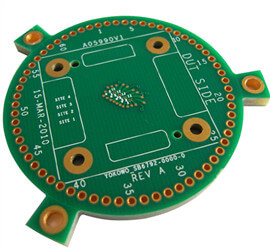

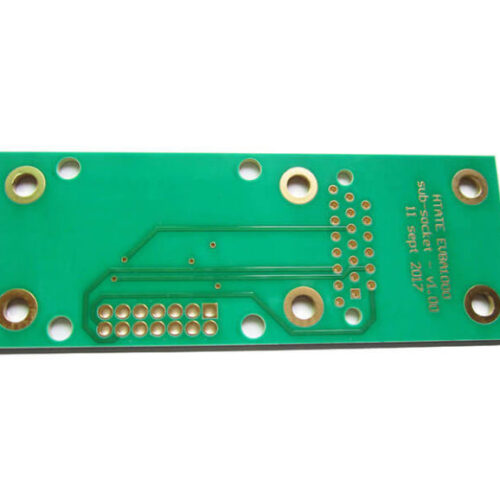

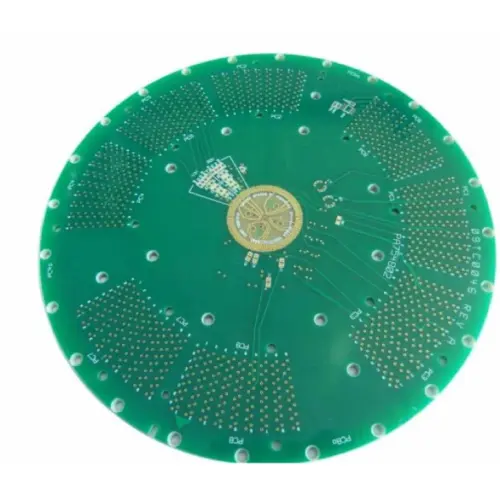

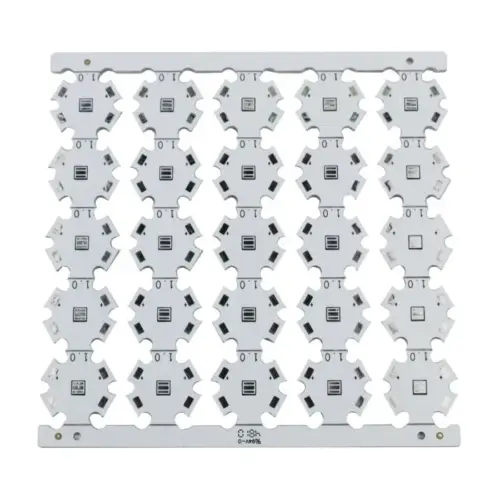

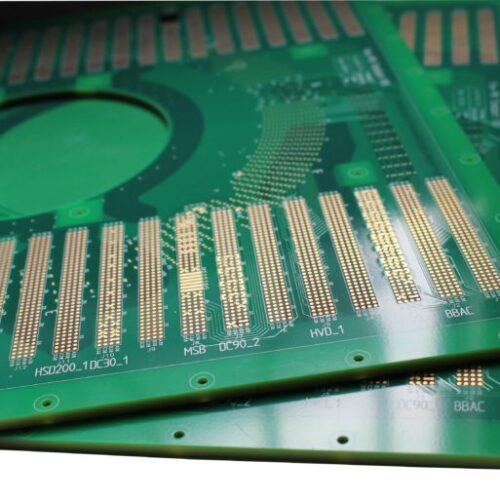

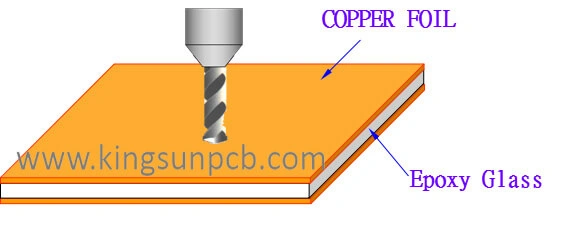

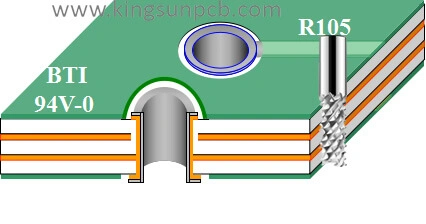

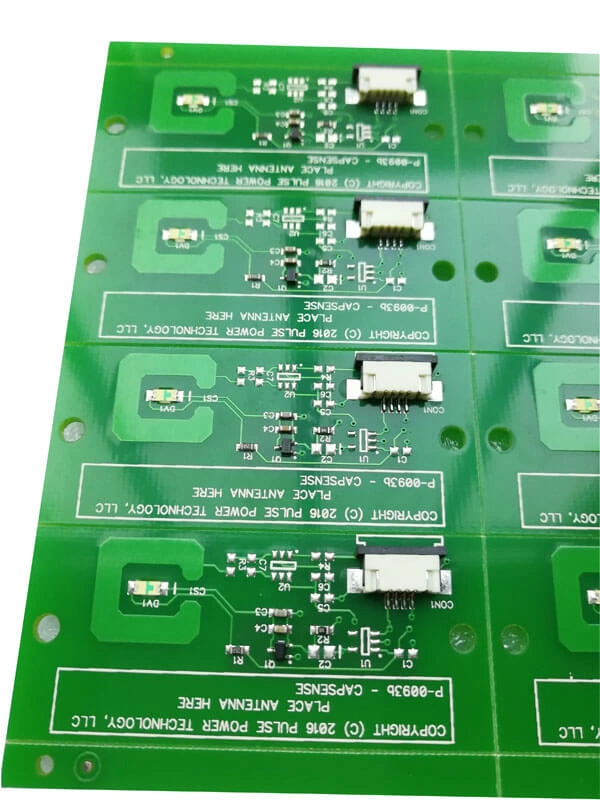

Rigid PCB board is a circuit board made of hard materials such as glass fiber reinforced resin.

Rigid PCB materials include phenolic paper laminate, epoxy paper laminate, polyester glass felt laminate and epoxy glass cloth laminate.

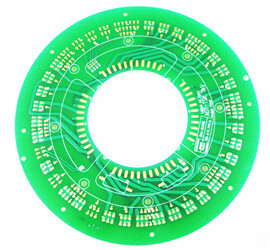

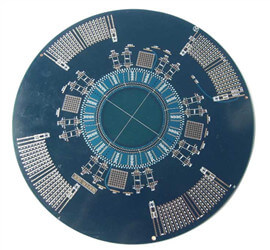

Flex PCB board is a flexible circuit board made of polyimide and polyester material, etc. The typical feature of the flexible board is the insulating film, and the flexible board uses a thin and soft insulating film to achieve insulation and mechanical strength.

Rigid And Flex PCB Design Are Different

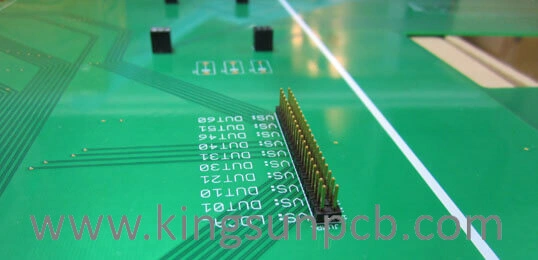

Rigid PCB design is to realize the integration of the circuit by laying out the electronic components on the circuit board, thereby improving the performance of the circuit, reducing failure and maintenance costs.

Flexible PCB circuit boards are designed to meet the needs of specific application scenarios, such as space-limited electronic devices that need to be bent, folded, or bent.

Rigid And Flex PCB Applications Are Different

Rigid PCB is often used in applications that need to be stronger, such as inside computers or in some mechanical and industrial products.

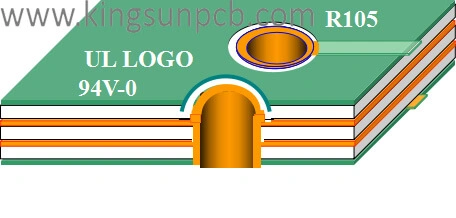

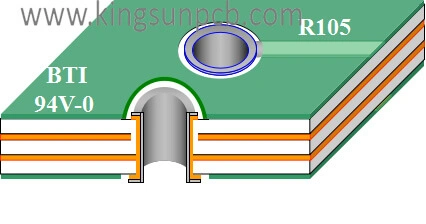

The electrical performance of the rigid PCB board is more stable and reliable, and it is not easy to be deformed or damaged. They will not affect their performance due to changes in the environment and can be more suitable for high-density wiring.

Flexible Leiterplatten werden häufig in Anwendungen eingesetzt, die Biegen und Krümmen erfordern, wie beispielsweise bei einigen hochpräzisen, leichten elektronischen Geräten, Uhren, Autokarosserien usw.

Advantages Of Rigid And Flex PCB

Rigid PCB board has the characteristics of firmness, wear resistance, high temperature resistance, etc., and has good thermal performance, which can evenly distribute the heat generation of components.

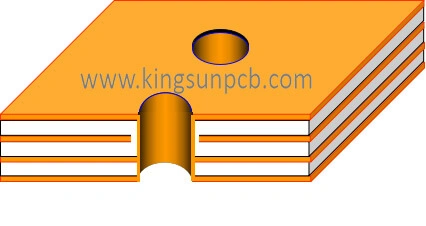

multilayer rigid PCB can connect multiple circuits together, effectively reducing space and making the originally complicated circuits more compact.

FPC PCB board has higher flexibility, adaptability and can assemble electronic components in more complex shapes.

In addition, FPC circuit board also has the advantages of being lightweight, small size and high reliability, so it is widely used in mobile devices, wireless communications, medical equipment, automotive electronics and other fields.