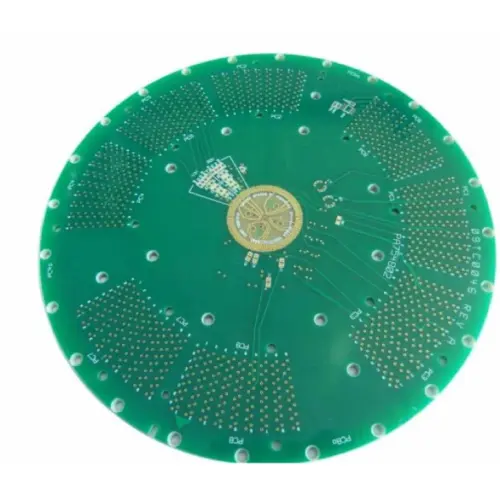

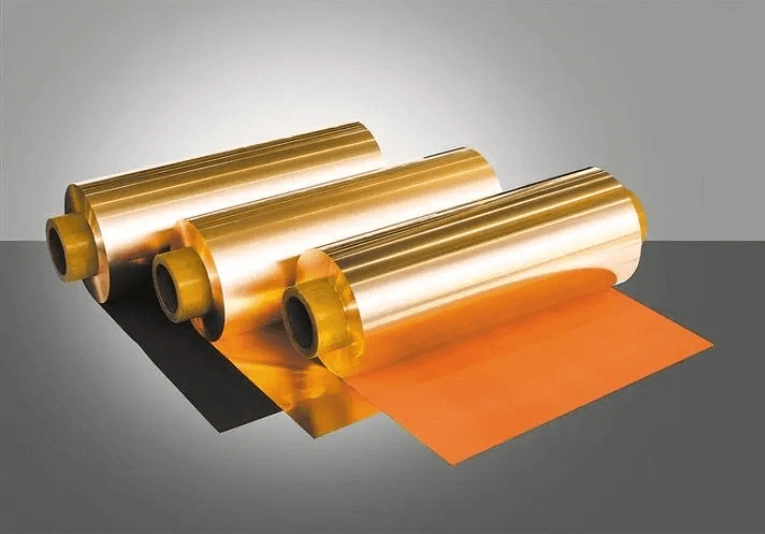

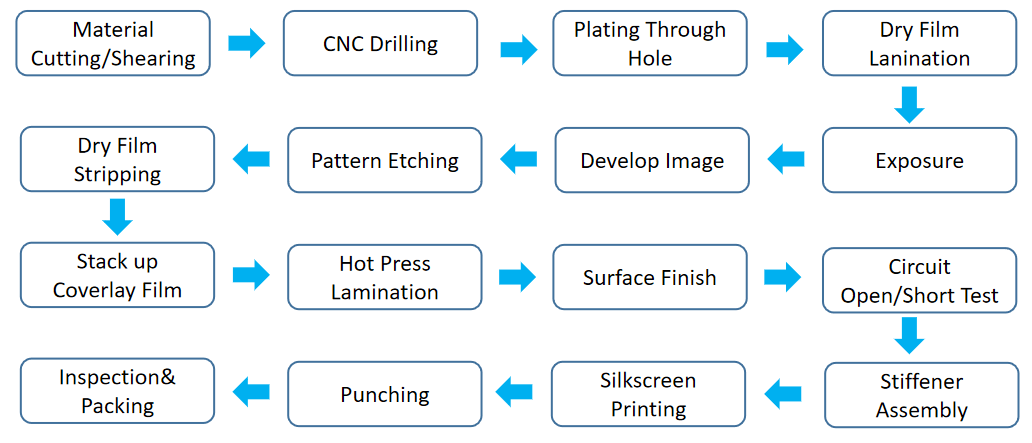

Corte/corte de materiais

The flexible printed circuit board material is generally a roll of 250mm wide 50M or 100M long PI base material covered with a certain thickness of copper on one or both sides of the copper foil. Therefore, we need to cut the large roll into a work board according to the size of the manufacturer’s instructions.

Perfuração CNC de PCB Flexível

A perfuração é a segunda parada no processo de fabricação de placas de circuito impresso flexíveis, e a qualidade da perfuração está diretamente relacionada à função e precisão do produto.

Along with the continuous development of high-density flexible PCB, Traditional mechanical drilling technology can no longer meet the market demand for small hole diameter, high precision and high efficiency. Laser drilling has become the mainstream processing technology for flexible PCB microvias.

Chapeamento através do furo

VCP electroplating line using Faraday’s theorem (the thickness of the coating is proportional to the current density and plating time) to plat the hole wall of the flexible printed circuit board to copper thickness following IPC standard or required by customer.

Laminação de Filme Seco

Composed of PE, photoresist and PET, paste dry film on the flexible printed circuit board, so as to achieve the function of image transfer, and protect the circuit during the etching process.

Exposição

De acordo com a exposição do filme correspondente ao trabalho, a imagem do filme gráfico de circuito impresso flexível é transferida para o filme seco (concluído na oficina livre de poeira de 10.000 níveis), e o equipamento principal é uma máquina de exposição automática.

Desenvolver imagem

The part of the dry film that is not exposed to light will be washed off by NaCO3, and the dry film on the trace and copper will not be washed off. Useful wiring and copper of flexible printed circuit board are preserved

Gravura de Padrão

A gravação flexível de placas de circuito impresso é o processo de remoção de cobre indesejado de uma placa de circuito.

Etching has acid etching process (ferric chloride and copper chloride) and alkaline etching process (ammonia). The acid method is used to etch the inner layers of flexible printed circuit board, it is accurate and cheap but time consuming. The alkaline method is used to etch the outer layer of the flexible PCB, which is fast and expensive.

Decapagem de filme seco

Flexible printed circuit board dry film stripping removes the protective dry film layer on the FPC circuit board through a chemical reaction. This process is usually done using chemical solutions, which can decompose the chemical substances in the film layer and expose the flex printed circuit board.

O equipamento de revelação e remoção de filme de gravação é uma linha DES horizontal.

Empilhe a capa Flex PCB

Flexible printed circuit board coverlay film, generally also called protective film, protects the circuit from oxidation and covers it for subsequent surface treatment. If the area that does not need gold plating is covered with coverlay. In the subsequent SMT soldering, the role of prevent welding.

Laminação por prensagem a quente

Através de prensagem em alta temperatura e alta pressão, seguida de cozimento em alta temperatura, a cola termoendurecível entre a película de cobertura e a placa é curada para atingir a finalidade de os dois firmemente combinados. Os parâmetros de trabalho de cura são temperatura 150 ° C, 1H. Os principais equipamentos são prensas e fornos rápidos;

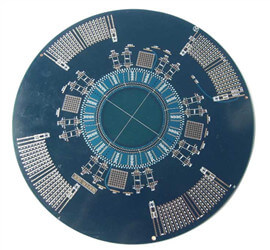

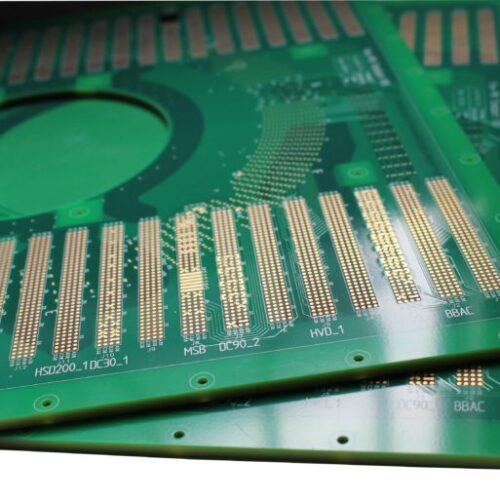

Acabamento de superfície de placa de circuito impresso flexível

O tratamento de superfície flexível da placa de circuito impresso é feito principalmente por imersão em ouro ou ENEPIG. De acordo com as necessidades do cliente, metais como níquel e ouro são depositados nas almofadas expostas do PCB flexível usando princípios químicos ou de galvanoplastia para proteger as almofadas e manter sua soldabilidade. O equipamento principal é linha banhada a ouro e linha banhada a ouro.

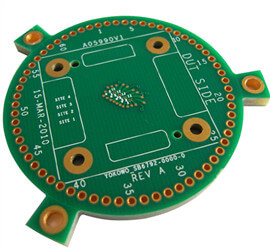

Teste de circuito aberto/curto flexível

Check whether there are open and short circuits between different networks of the flexible printed circuit board, four-wire failure, etc. through test fixtures or equipment. The main equipment is an electric test machine and a flying probe test machine;

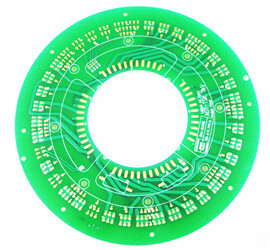

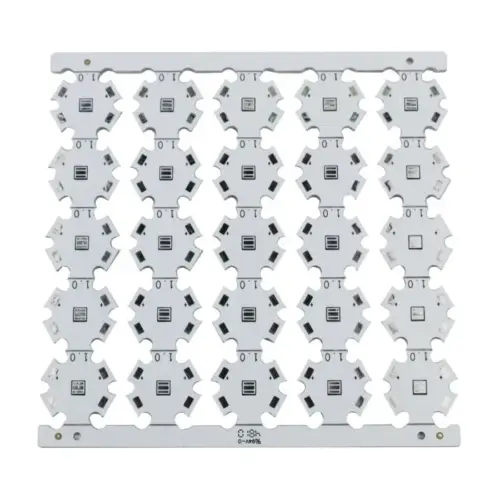

Conjunto flexível de reforço de PCB

O objetivo da colagem do reforço Flex PCB é fortalecer a resistência mecânica da placa de circuito impresso flexível e facilitar a montagem de peças na superfície do PCB.

Os materiais de reforço FPC são reforço de poliimida comum, reforço FR4 e reforço de aço.

FR4 stiffener main components are glass fiber cloth and epoxy resin glue, which is the same as the FR4 material used in PCB.

Steel stiffener is made of steel, which has strong hardness and support strength. Manual assembly is required, the process is more complicated, and the cost will be higher.

PI stiffener is as same as the coverlay film, consisting of PI and adhesive release paper, but the PI layer is thicker, can be processed and produced from 0.05mm to 0.25mm, the tolerance can be controlled at +/- 0.03mm, and the precision is high , high temperature resistance (100°C-280°C).

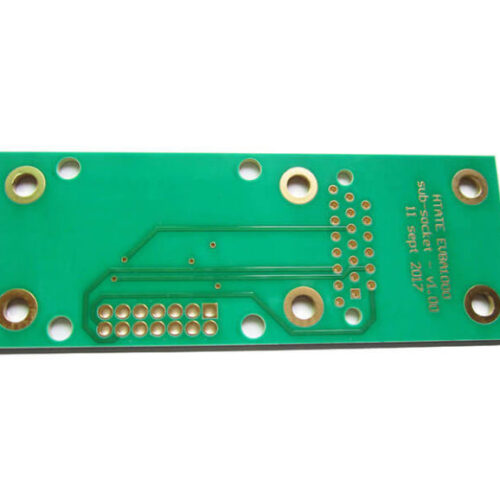

Impressão em serigrafia

Print the text ink on the flexible printed circuit board through the principle of screen printing, mainly printing the product model, production date code, and various component identifications required by customers, etc. The main equipment includes screen printing machines, ovens, text inkjet printers, etc.;

Perfuração flexível de PCB

Flexible printed circuit board punching is a link in the FPC process, which is equivalent to a cutting workstation. At present, the main equipment used in this workstation on the market is flex circuit punching machine and FPC UV laser cutting machine.

O princípio flexível da puncionadeira PCB é aplicar pressão através do cilindro para empurrar o molde da faca no transportador e realizar o corte do circuito flexível de uma só vez.

O princípio da máquina de corte a laser para placa de circuito impresso flexível é irradiar a superfície do FPC com um feixe de laser de alta energia e alta densidade e digitalizá-lo para frente e para trás através do espelho vibratório para formar uma camada de corte de material de vidro.

Inspeção e embalagem

Através da inspeção visual manual, CCD, equipamento para inspecionar completamente a aparência e a condição da superfície da placa de circuito impresso flexível, separar produtos bons de produtos defeituosos e realizar testes de confiabilidade no produto para confirmar se ele atende aos requisitos do cliente.

Packaging and shipping flex circuits are carried out according to customer requirements. The main packaging methods include vacuum packaging, micro-membrane packaging, tray packaging, etc.