| Article |

Paramètres techniques |

spécification |

| Largeur/espace minimum de ligne de circuit |

4/4 mil |

Épaisseur du cuivre fini 1 oz |

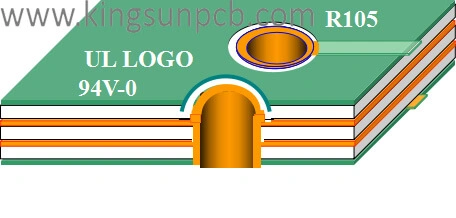

| Min MCPCB Pad Anneau de Via |

4 millions |

Distance entre le bord du trou et la périphérie de l'anneau |

| Min MCPCB Pad Ring de PTH |

6 millions |

Distance entre le bord du trou et la périphérie de l'anneau |

| Min. MCPCB via taille |

8 millions |

Épaisseur du panneau < 1,2 mm |

| Épaisseur minimale MCPCB du double face |

0,5 mm |

Épaisseur finale du panneau |

| Épaisseur minimale MCPCB du multicouche |

0,5 mm |

Épaisseur finale du panneau |

| Épaisseur maximale du MCPCB |

5,0 millimètres |

Épaisseur finale du panneau |

| Dimension maximale du MCPCB |

1200×600 millimètres |

PCB simple et double face |

| Espace entre la ligne et le bord de la planche |

10 millions |

Fraisage du contour |

| Couches MCPCB maximales |

8 couches |

|

| Couleur du masque de soudure MCPCB |

Green, Black, Blue, Red, White, Yellow |

|

| Couleur de sérigraphie MCPCB |

White,Black,Yellow |

|

| Finition de surface MCPCB |

HASL, ENIG, ENEPIG, ImAg, ImTin, OSP |

|

| Épaisseur maximale de cuivre de finition |

10 oz |

|

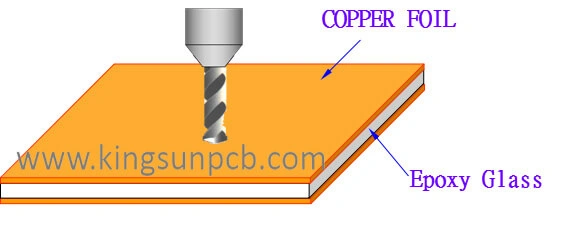

| Épaisseur diélectrique |

4 millions |

|

| Matériel MCPCB |

Aluminium 1100,3003,5052,6061. Cuivre, Fer |

|

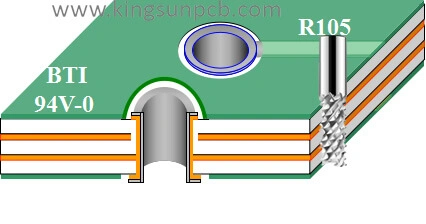

| Technologie spéciale |

MCPCB aveugle et enterré, fente en T, trou fraisé |

|

-gallery-770x578-1-500x500.jpg)