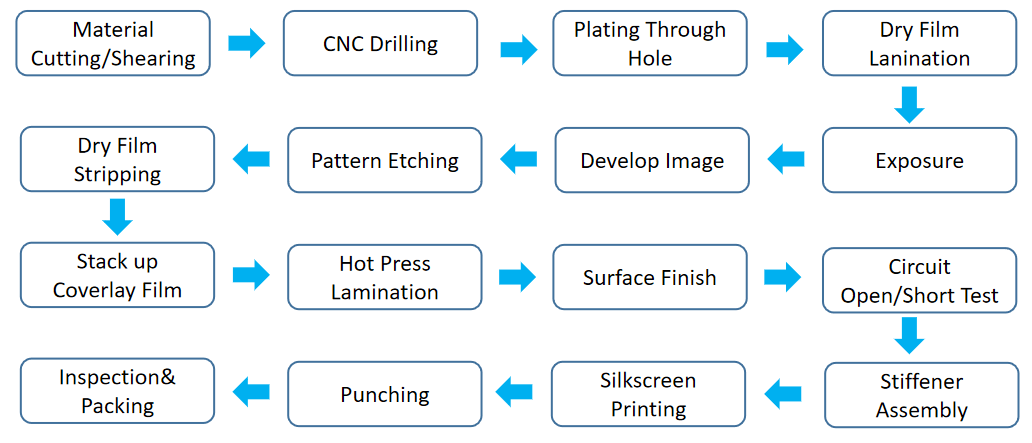

Coupe/cisaillement de matériaux

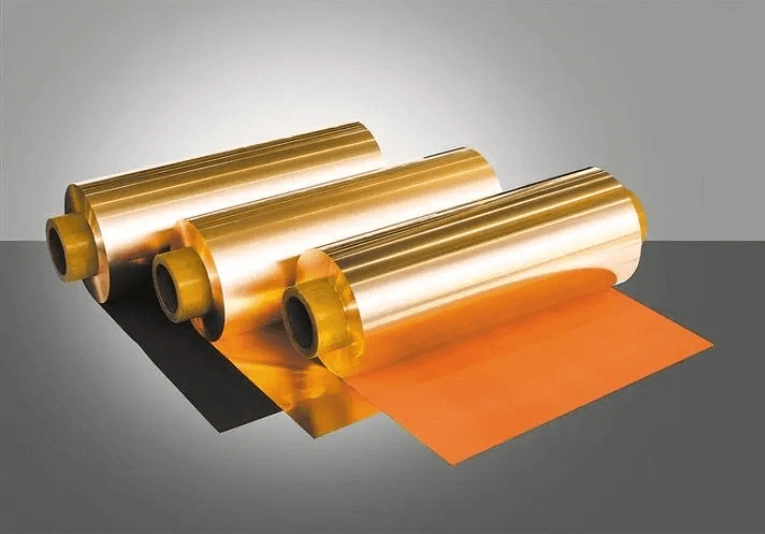

The flexible printed circuit board material is generally a roll of 250mm wide 50M or 100M long PI base material covered with a certain thickness of copper on one or both sides of the copper foil. Therefore, we need to cut the large roll into a work board according to the size of the manufacturer’s instructions.

Perçage CNC de PCB flexibles

Le perçage est la deuxième étape du processus de fabrication des circuits imprimés flexibles, et la qualité du perçage est directement liée à la fonction et à la précision du produit.

Along with the continuous development of high-density flexible PCB, Traditional mechanical drilling technology can no longer meet the market demand for small hole diameter, high precision and high efficiency. Laser drilling has become the mainstream processing technology for flexible PCB microvias.

Placage à travers le trou

VCP electroplating line using Faraday’s theorem (the thickness of the coating is proportional to the current density and plating time) to plat the hole wall of the flexible printed circuit board to copper thickness following IPC standard or required by customer.

Stratification de film sec

Composed of PE, photoresist and PET, paste dry film on the flexible printed circuit board, so as to achieve the function of image transfer, and protect the circuit during the etching process.

Exposition

Selon l'exposition du film correspondant au travail, l'image du film graphique flexible du circuit imprimé est transférée sur le film sec (réalisé dans l'atelier sans poussière de niveau 10 000), et l'équipement principal est une machine d'exposition automatique.

Développer l’image

The part of the dry film that is not exposed to light will be washed off by NaCO3, and the dry film on the trace and copper will not be washed off. Useful wiring and copper of flexible printed circuit board are preserved

Gravure de motifs

La gravure flexible de circuits imprimés est le processus consistant à éliminer le cuivre indésirable d’un circuit imprimé.

Etching has acid etching process (ferric chloride and copper chloride) and alkaline etching process (ammonia). The acid method is used to etch the inner layers of flexible printed circuit board, it is accurate and cheap but time consuming. The alkaline method is used to etch the outer layer of the flexible PCB, which is fast and expensive.

Décapage de film sec

Flexible printed circuit board dry film stripping removes the protective dry film layer on the FPC circuit board through a chemical reaction. This process is usually done using chemical solutions, which can decompose the chemical substances in the film layer and expose the flex printed circuit board.

L'équipement de développement et de retrait du film de gravure est une ligne DES horizontale.

Empilez la couverture de PCB flexible

Flexible printed circuit board coverlay film, generally also called protective film, protects the circuit from oxidation and covers it for subsequent surface treatment. If the area that does not need gold plating is covered with coverlay. In the subsequent SMT soldering, the role of prevent welding.

Stratification à chaud

Grâce à un pressage à haute température et à haute pression, suivi d'une cuisson à haute température, la colle thermodurcissable entre le film de couverture et le panneau est durcie pour atteindre l'objectif des deux étroitement combinés. Les paramètres de travail de durcissement sont la température 150°C, 1H. L'équipement principal est constitué de presses et de fours rapides ;

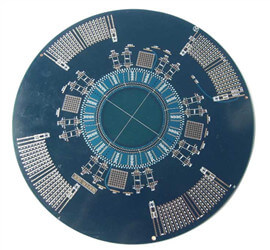

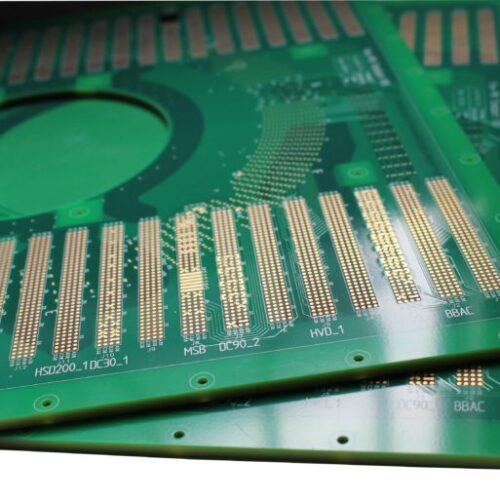

Finition de surface de carte de circuit imprimé flexible

Le traitement de surface des circuits imprimés flexibles se fait principalement par immersion or ou ENEPIG. Selon les exigences du client, des métaux tels que le nickel et l'or sont déposés sur les plages exposées des PCB flexibles en utilisant des principes chimiques ou de galvanoplastie pour protéger les plages et maintenir leur soudabilité. L'équipement principal est une ligne plaquée or et une ligne plaquée or.

Test d'ouverture/court-circuit de circuit flexible

Check whether there are open and short circuits between different networks of the flexible printed circuit board, four-wire failure, etc. through test fixtures or equipment. The main equipment is an electric test machine and a flying probe test machine;

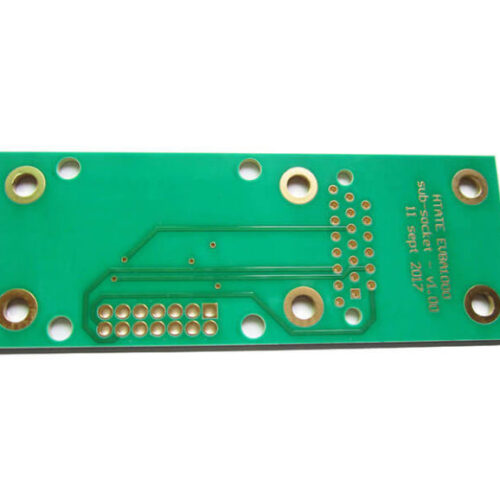

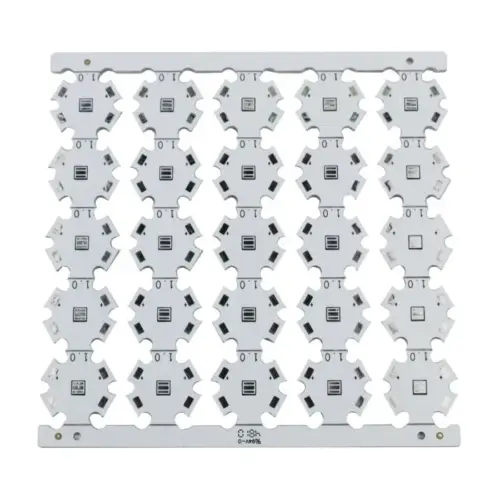

Assemblage flexible de raidisseur de carte PCB

Le but du collage du raidisseur Flex PCB est de renforcer la résistance mécanique du circuit imprimé flexible et de faciliter le montage des pièces sur la surface du PCB.

Les matériaux de raidisseur FPC sont les raidisseurs courants en polyimide, les raidisseurs FR4 et les raidisseurs en acier.

FR4 stiffener main components are glass fiber cloth and epoxy resin glue, which is the same as the FR4 material used in PCB.

Steel stiffener is made of steel, which has strong hardness and support strength. Manual assembly is required, the process is more complicated, and the cost will be higher.

PI stiffener is as same as the coverlay film, consisting of PI and adhesive release paper, but the PI layer is thicker, can be processed and produced from 0.05mm to 0.25mm, the tolerance can be controlled at +/- 0.03mm, and the precision is high , high temperature resistance (100°C-280°C).

Sérigraphie

Print the text ink on the flexible printed circuit board through the principle of screen printing, mainly printing the product model, production date code, and various component identifications required by customers, etc. The main equipment includes screen printing machines, ovens, text inkjet printers, etc.;

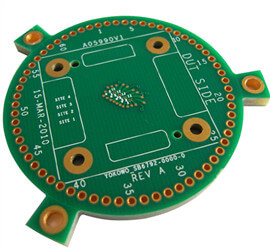

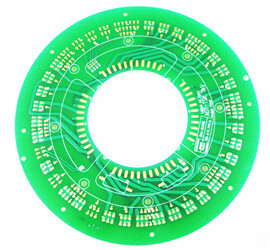

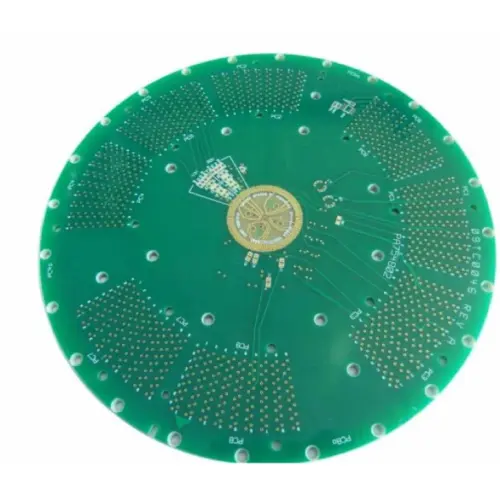

Poinçonnage flexible des PCB

Flexible printed circuit board punching is a link in the FPC process, which is equivalent to a cutting workstation. At present, the main equipment used in this workstation on the market is flex circuit punching machine and FPC UV laser cutting machine.

Le principe de la poinçonneuse flexible pour PCB consiste à appliquer une pression à travers le cylindre pour pousser le moule à couteau dans le support et réaliser la découpe du circuit flexible en une seule fois.

Le principe de la machine de découpe laser pour circuits imprimés flexibles est d'irradier la surface du FPC avec un faisceau laser à haute énergie et haute densité et de le balayer d'avant en arrière à travers le miroir vibrant pour former une couche coupante de matériau en verre.

Inspection et emballage

Grâce à une inspection visuelle manuelle, un CCD et un équipement permettant d'inspecter entièrement l'apparence et l'état de surface de la carte de circuit imprimé flexible, de séparer les bons produits des produits défectueux et d'effectuer des tests de fiabilité sur le produit pour confirmer s'il répond aux exigences du client.

Packaging and shipping flex circuits are carried out according to customer requirements. The main packaging methods include vacuum packaging, micro-membrane packaging, tray packaging, etc.