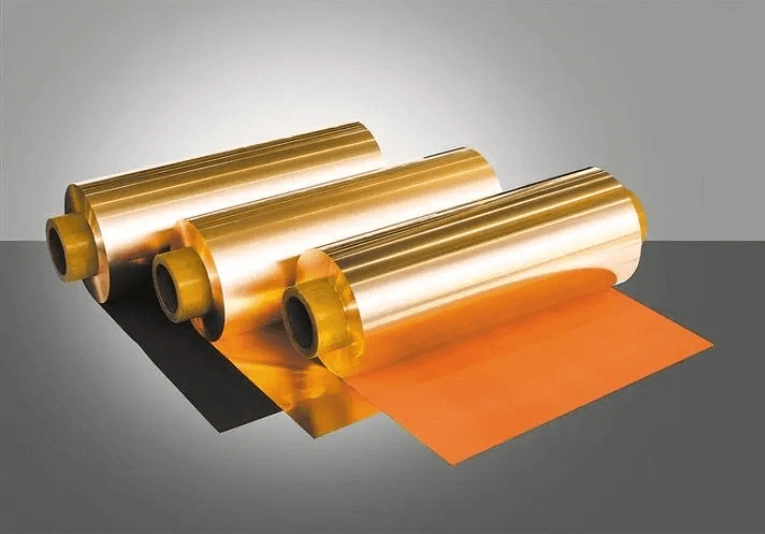

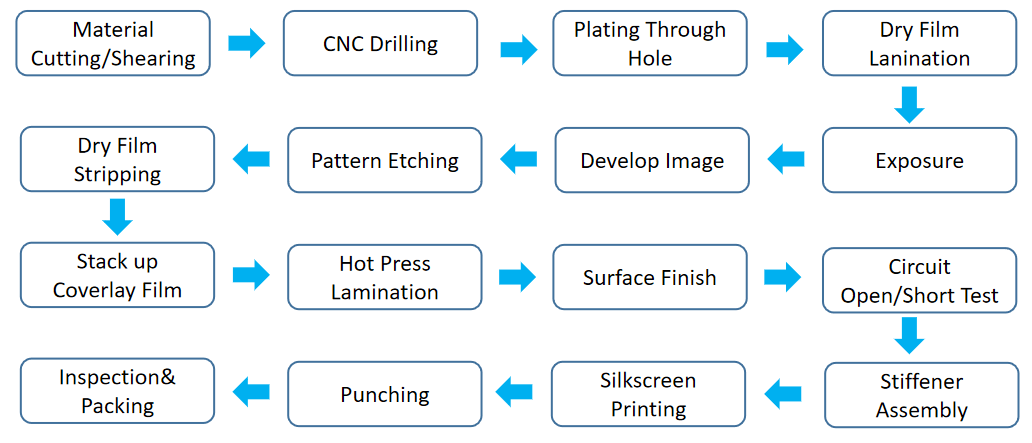

Taglio/Cesonatura del materiale

The flexible printed circuit board material is generally a roll of 250mm wide 50M or 100M long PI base material covered with a certain thickness of copper on one or both sides of the copper foil. Therefore, we need to cut the large roll into a work board according to the size of the manufacturer’s instructions.

Foratura CNC di PCB flessibili

La perforazione è la seconda tappa del processo di produzione dei circuiti stampati flessibili e la qualità della perforazione è direttamente correlata alla funzione e alla precisione del prodotto.

Along with the continuous development of high-density flexible PCB, Traditional mechanical drilling technology can no longer meet the market demand for small hole diameter, high precision and high efficiency. Laser drilling has become the mainstream processing technology for flexible PCB microvias.

Foro passante per placcatura

VCP electroplating line using Faraday’s theorem (the thickness of the coating is proportional to the current density and plating time) to plat the hole wall of the flexible printed circuit board to copper thickness following IPC standard or required by customer.

Laminazione con film secco

Composed of PE, photoresist and PET, paste dry film on the flexible printed circuit board, so as to achieve the function of image transfer, and protect the circuit during the etching process.

Esposizione

In base all'esposizione della pellicola corrispondente al lavoro di lavoro, l'immagine della pellicola grafica flessibile del circuito stampato viene trasferita alla pellicola secca (completata nell'officina senza polvere a 10.000 livelli) e l'attrezzatura principale è una macchina di esposizione automatica.

Sviluppa immagine

The part of the dry film that is not exposed to light will be washed off by NaCO3, and the dry film on the trace and copper will not be washed off. Useful wiring and copper of flexible printed circuit board are preserved

Acquaforte del modello

L'incisione flessibile del circuito stampato è il processo di rimozione del rame indesiderato da un circuito.

Etching has acid etching process (ferric chloride and copper chloride) and alkaline etching process (ammonia). The acid method is used to etch the inner layers of flexible printed circuit board, it is accurate and cheap but time consuming. The alkaline method is used to etch the outer layer of the flexible PCB, which is fast and expensive.

Spellatura della pellicola secca

Flexible printed circuit board dry film stripping removes the protective dry film layer on the FPC circuit board through a chemical reaction. This process is usually done using chemical solutions, which can decompose the chemical substances in the film layer and expose the flex printed circuit board.

L'attrezzatura per la rimozione della pellicola di sviluppo e incisione è una linea DES orizzontale.

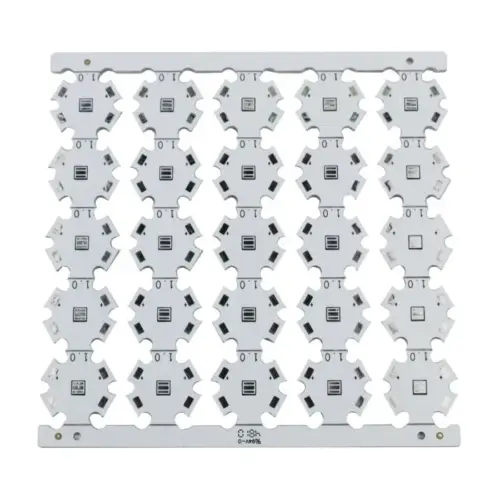

Impila la copertura PCB flessibile

Flexible printed circuit board coverlay film, generally also called protective film, protects the circuit from oxidation and covers it for subsequent surface treatment. If the area that does not need gold plating is covered with coverlay. In the subsequent SMT soldering, the role of prevent welding.

Laminazione con pressa a caldo

Attraverso la pressatura ad alta temperatura e alta pressione, seguita da una cottura a calore elevato, la colla termoindurente tra la pellicola di copertura e il pannello viene polimerizzata per raggiungere lo scopo dei due strettamente combinati. I parametri di lavoro di polimerizzazione sono temperatura 150 ° C, 1H. Le attrezzature principali sono presse e forni veloci;

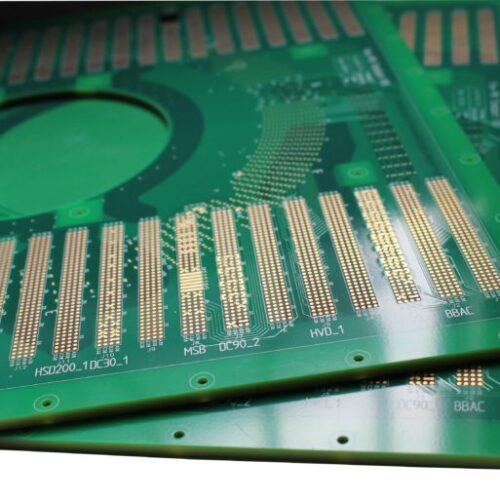

Finitura superficiale flessibile del circuito stampato

Il trattamento superficiale dei circuiti stampati flessibili viene eseguito principalmente tramite oro ad immersione o ENEPIG. In base alle esigenze del cliente, metalli come nichel e oro vengono depositati sui pad esposti del PCB flessibile utilizzando principi chimici o galvanici per proteggere i pad e mantenerne la saldabilità. L'attrezzatura principale è la linea placcata in oro e la linea placcata in oro.

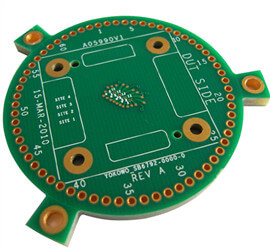

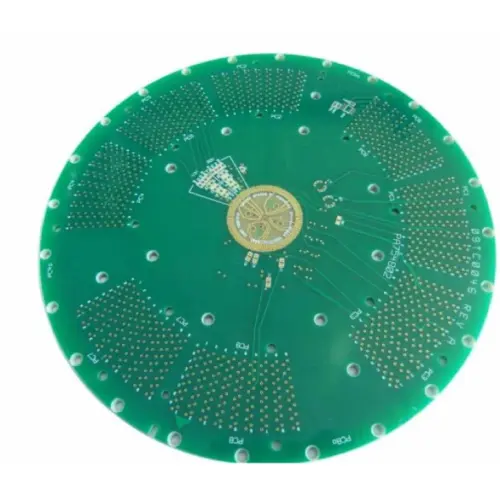

Test di circuito aperto/cortocircuito flessibile

Check whether there are open and short circuits between different networks of the flexible printed circuit board, four-wire failure, etc. through test fixtures or equipment. The main equipment is an electric test machine and a flying probe test machine;

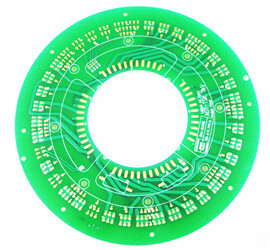

Gruppo di rinforzo PCB flessibile

Lo scopo dell'incollaggio del rinforzo Flex PCB è quello di rafforzare la resistenza meccanica del circuito stampato flessibile e facilitare il montaggio delle parti sulla superficie del PCB.

I materiali di rinforzo FPC sono il comune rinforzo in poliimmide, il rinforzo FR4 e il rinforzo in acciaio.

FR4 stiffener main components are glass fiber cloth and epoxy resin glue, which is the same as the FR4 material used in PCB.

Steel stiffener is made of steel, which has strong hardness and support strength. Manual assembly is required, the process is more complicated, and the cost will be higher.

PI stiffener is as same as the coverlay film, consisting of PI and adhesive release paper, but the PI layer is thicker, can be processed and produced from 0.05mm to 0.25mm, the tolerance can be controlled at +/- 0.03mm, and the precision is high , high temperature resistance (100°C-280°C).

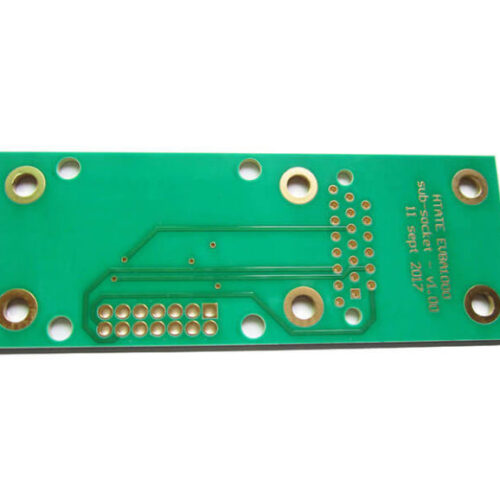

Stampa serigrafica

Print the text ink on the flexible printed circuit board through the principle of screen printing, mainly printing the product model, production date code, and various component identifications required by customers, etc. The main equipment includes screen printing machines, ovens, text inkjet printers, etc.;

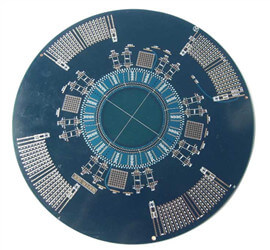

Punzonatura PCB flessibile

Flexible printed circuit board punching is a link in the FPC process, which is equivalent to a cutting workstation. At present, the main equipment used in this workstation on the market is flex circuit punching machine and FPC UV laser cutting machine.

Il principio della punzonatrice flessibile per PCB consiste nell'applicare pressione attraverso il cilindro per spingere lo stampo del coltello nel supporto e realizzare il taglio del circuito flessibile in una sola volta.

Il principio della macchina da taglio laser per circuiti stampati flessibili è quello di irradiare la superficie dell'FPC con un raggio laser ad alta energia e alta densità e scansionarlo avanti e indietro attraverso lo specchio vibrante per formare uno strato di taglio di materiale di vetro.

Ispezione e imballaggio

Attraverso l'ispezione visiva manuale, CCD, apparecchiature per ispezionare completamente l'aspetto e le condizioni superficiali del circuito stampato flessibile, separare i prodotti buoni da quelli difettosi ed eseguire test di affidabilità sul prodotto per confermare se soddisfa i requisiti del cliente.

Packaging and shipping flex circuits are carried out according to customer requirements. The main packaging methods include vacuum packaging, micro-membrane packaging, tray packaging, etc.