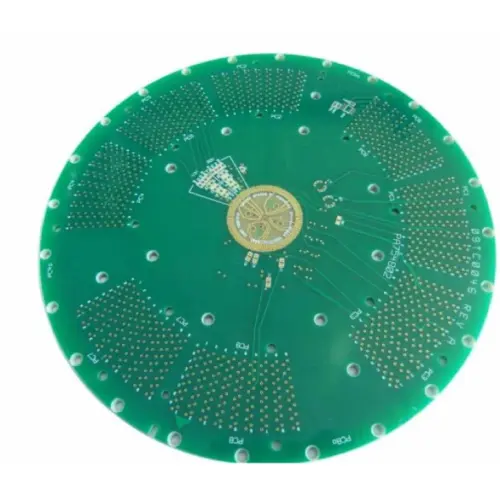

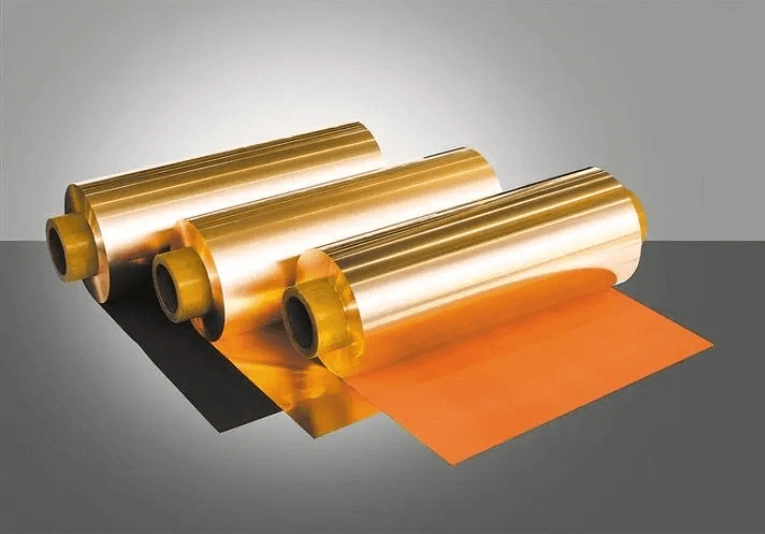

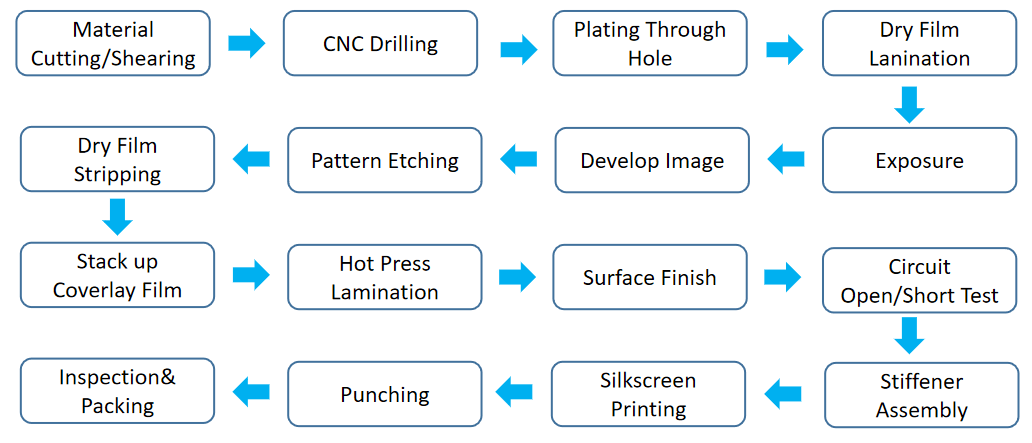

Materiaal snijden/scheren

The flexible printed circuit board material is generally a roll of 250mm wide 50M or 100M long PI base material covered with a certain thickness of copper on one or both sides of the copper foil. Therefore, we need to cut the large roll into a work board according to the size of the manufacturer’s instructions.

CNC-boren van flexibele PCB's

Boren is de tweede stop in het productieproces van flexibele printplaten, en de kwaliteit van het boren houdt rechtstreeks verband met de functie en nauwkeurigheid van het product.

Along with the continuous development of high-density flexible PCB, Traditional mechanical drilling technology can no longer meet the market demand for small hole diameter, high precision and high efficiency. Laser drilling has become the mainstream processing technology for flexible PCB microvias.

Plateren door gat

VCP electroplating line using Faraday’s theorem (the thickness of the coating is proportional to the current density and plating time) to plat the hole wall of the flexible printed circuit board to copper thickness following IPC standard or required by customer.

Lamineren van droge films

Composed of PE, photoresist and PET, paste dry film on the flexible printed circuit board, so as to achieve the function of image transfer, and protect the circuit during the etching process.

Blootstelling

Afhankelijk van de filmbelichting die overeenkomt met de werkzaamheden, wordt het beeld van de flexibele grafische film met gedrukte schakeling overgebracht naar de droge film (voltooid in de stofvrije werkplaats met 10.000 niveaus) en is de belangrijkste uitrusting een automatische belichtingsmachine.

Ontwikkel imago

The part of the dry film that is not exposed to light will be washed off by NaCO3, and the dry film on the trace and copper will not be washed off. Useful wiring and copper of flexible printed circuit board are preserved

Patroon etsen

Flexibel etsen van printplaten is het proces waarbij ongewenst koper van een printplaat wordt verwijderd.

Etching has acid etching process (ferric chloride and copper chloride) and alkaline etching process (ammonia). The acid method is used to etch the inner layers of flexible printed circuit board, it is accurate and cheap but time consuming. The alkaline method is used to etch the outer layer of the flexible PCB, which is fast and expensive.

Droge filmstrippen

Flexible printed circuit board dry film stripping removes the protective dry film layer on the FPC circuit board through a chemical reaction. This process is usually done using chemical solutions, which can decompose the chemical substances in the film layer and expose the flex printed circuit board.

De apparatuur voor het verwijderen van ontwikkel- en etsfilms is een horizontale DES-lijn.

Stapel Flex PCB-coverlay op elkaar

Flexible printed circuit board coverlay film, generally also called protective film, protects the circuit from oxidation and covers it for subsequent surface treatment. If the area that does not need gold plating is covered with coverlay. In the subsequent SMT soldering, the role of prevent welding.

Lamineren met warme pers

Door middel van persen bij hoge temperatuur en hoge druk, gevolgd door bakken bij hoge temperaturen, wordt de thermohardende lijm tussen de afdekfilm en de plaat uitgehard om het doel van de twee nauw verbonden te bereiken. De uithardingsparameters zijn temperatuur 150 ° C, 1 uur. De belangrijkste uitrusting bestaat uit snelle persen en ovens;

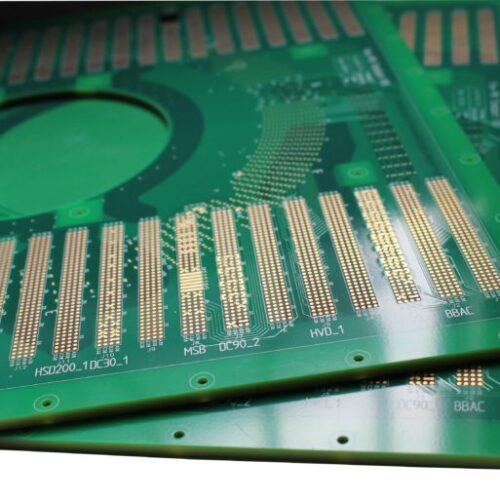

Flexibele oppervlakteafwerking van de printplaat

Flexibele oppervlaktebehandeling van printplaten wordt voornamelijk gedaan door middel van immersiegoud of ENEPIG. Volgens de eisen van de klant worden metalen zoals nikkel en goud op de blootliggende pads van flexibele PCB's afgezet door chemische of galvanische principes te gebruiken om de pads te beschermen en hun soldeerbaarheid te behouden. De belangrijkste uitrusting is vergulde lijn en vergulde lijn.

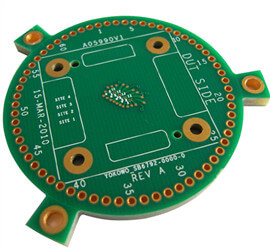

Flexibel circuit open/kortsluitingstest

Check whether there are open and short circuits between different networks of the flexible printed circuit board, four-wire failure, etc. through test fixtures or equipment. The main equipment is an electric test machine and a flying probe test machine;

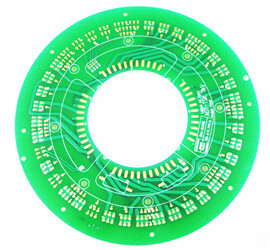

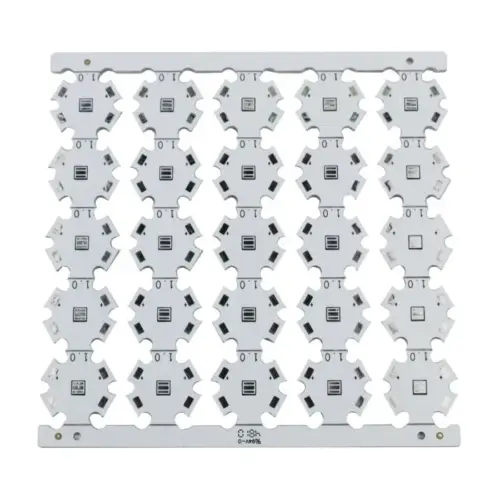

Flexibele PCB-versteviging

Het doel van het verlijmen van Flex PCB-verstijvers is om de mechanische sterkte van de flexibele printplaat te versterken en de montage van onderdelen op het oppervlak van de PCB te vergemakkelijken.

FPC-verstijvingsmaterialen zijn gewone polyimide-verstijvers, FR4-verstijvers en stalen verstijvers.

FR4 stiffener main components are glass fiber cloth and epoxy resin glue, which is the same as the FR4 material used in PCB.

Steel stiffener is made of steel, which has strong hardness and support strength. Manual assembly is required, the process is more complicated, and the cost will be higher.

PI stiffener is as same as the coverlay film, consisting of PI and adhesive release paper, but the PI layer is thicker, can be processed and produced from 0.05mm to 0.25mm, the tolerance can be controlled at +/- 0.03mm, and the precision is high , high temperature resistance (100°C-280°C).

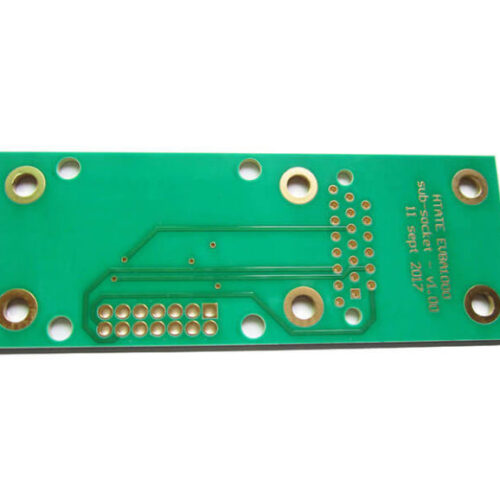

Zeefdruk

Print the text ink on the flexible printed circuit board through the principle of screen printing, mainly printing the product model, production date code, and various component identifications required by customers, etc. The main equipment includes screen printing machines, ovens, text inkjet printers, etc.;

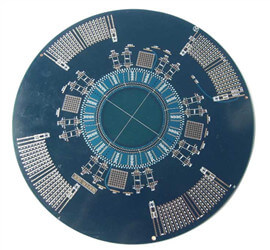

Flexibel PCB-ponsen

Flexible printed circuit board punching is a link in the FPC process, which is equivalent to a cutting workstation. At present, the main equipment used in this workstation on the market is flex circuit punching machine and FPC UV laser cutting machine.

Het principe van de flexibele PCB-ponsmachine is om druk door de cilinder uit te oefenen om de mesvorm in de drager te duwen en het flexcircuit in één keer te snijden.

Het principe van de flexibele lasersnijmachine voor printplaten is om het oppervlak van de FPC te bestralen met een laserstraal met hoge energie en hoge dichtheid en deze heen en weer te scannen door de trillende spiegel om een snijdende laag glasmateriaal te vormen.

Inspectie en verpakking

Door middel van handmatige visuele inspectie, CCD, apparatuur om het uiterlijk en de toestand van het oppervlak van de flexibele printplaat volledig te inspecteren, goede producten van defecte producten te scheiden en betrouwbaarheidstests op het product uit te voeren om te bevestigen of het aan de eisen van de klant voldoet.

Packaging and shipping flex circuits are carried out according to customer requirements. The main packaging methods include vacuum packaging, micro-membrane packaging, tray packaging, etc.