Materiaal knippen

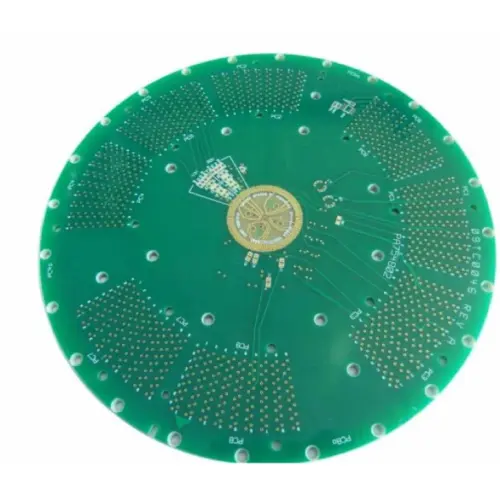

Rigid flex board and flexible PCB board with single-sided, and it is not allowed to cut single-sided sheet directly. They need to be etched into single-sided sheet from 2 layer flex PCB to ensure the bonding force between layers and avoid delamination.

Binnenlaagcircuit

Check FlexPCB is flat without discounts, wrinkles, and no glue stains on the board surface, etc.

All flex board PCB must be attached to the pallet for development and etching, and one pallet is attached to one flex PCB to prevent the flex PCB from being folded and wrinkled due to etching transmission problems.

All boards must pass through AOI, and flex printed circuit does not allow supplementary lines.

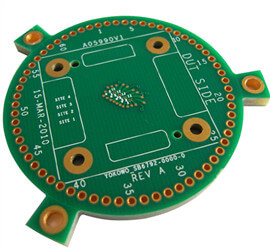

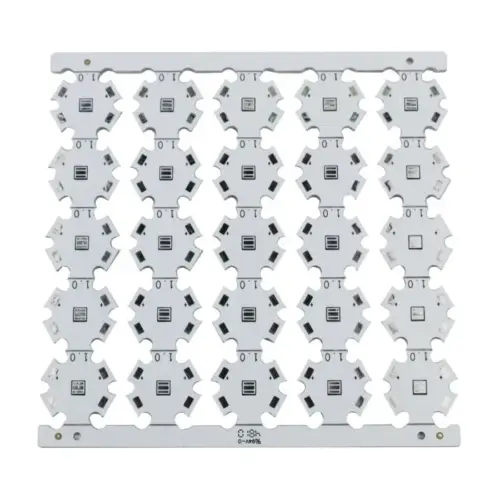

Rigid Flex PCB-laminering

Rigid flex PCB board lamination must use a special program, the lamination program can not be mixed with other boards

Wanneer de flexprint bruin is, moet deze met een pallet worden bevestigd. Na het bruinen wordt de flexibele printplaat met rimpels weggegooid. Vóór het klinken moet de flexibele printplaat goed bruin worden.

After riveting FR-4, flex PCB and No-Flow PP, first check whether there is less or more PP, and then use X-Ray to check whether there is layer deviation.

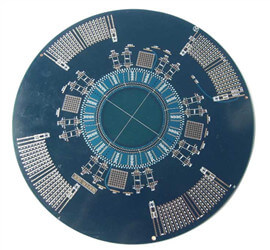

NC-boren

Rigid Flex PCB-boren is een proces van PCB-productie en het is ook een zeer belangrijke stap.

Het inspectieproces richt zich op het controleren of er geen lijmresten op de flexibele printplaat aanwezig zijn ter hoogte van de T-positie van de stijve en flexibele printplaatverbinding. Als er sprake is van een afwijking, meld dit dan tijdig bij het proces voor vervolgafhandeling.

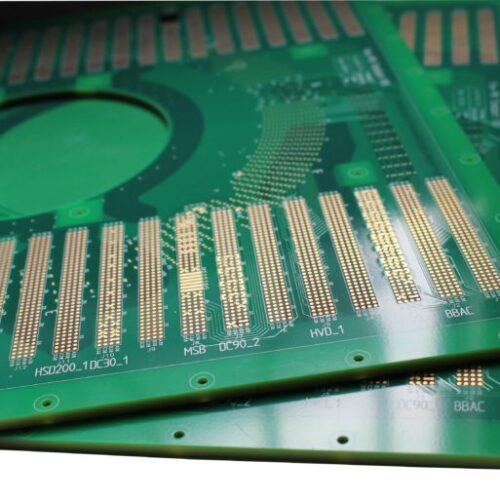

Plateren door gat

The program for desmearing the rigid flex board is a special program, please pay attention to the switching of the desmearing program before copper plating.

After removing the slag, the rigid flexible printed circuit board is copper-precipitated according to the 2 layer PCB procedure after the PI is adjusted. The PI potion is prepared according to the volume concentration of 40%. The working temperature of the potion is 40°C, and the adjustment time is 4~8MIN.

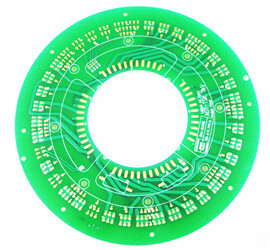

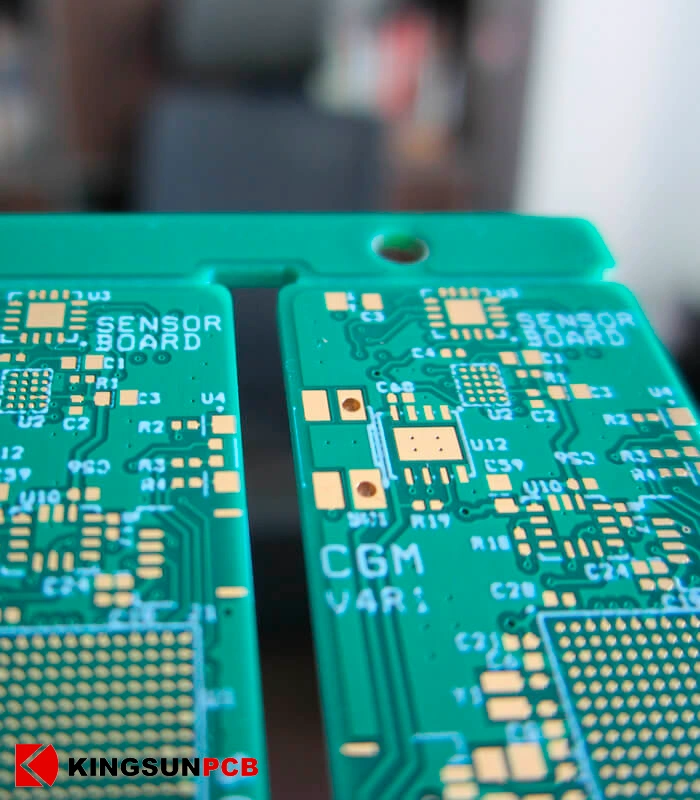

Rigid Flex printplaatopeningstechnologie

The rigid flex board is not an ordinary circuit board, but is composed of a rigid circuit board and a flex circuit board. The flexible area of the rigid flex PCB board is formed by removing the rigid layer in the area, leaving only the flexible layer, and removing the rigid layer. The whole process called opening technology.

There are three ways to opening the rigid flexible board: laser opening, gong machine-controlled deep opening and V-CUT opening.

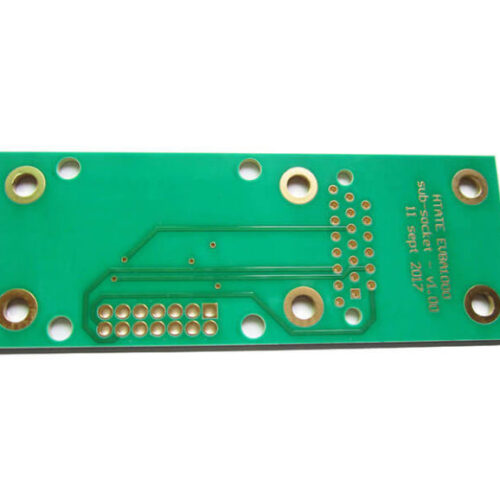

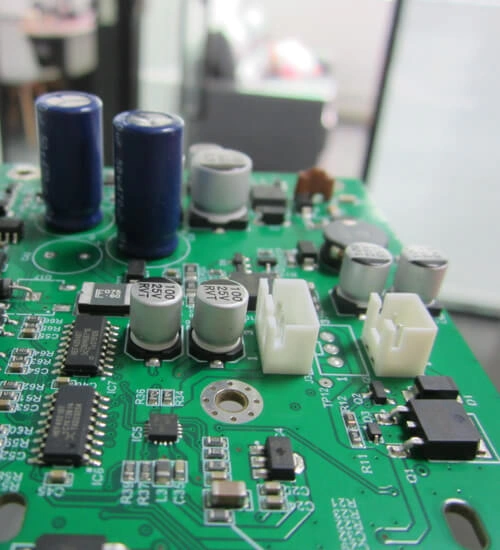

Stijve flexibele PCB-circuit open-kortsluitingstest

The electrical performance of the rigid flex PCB is usually achieved through the PCB open-short circuit test. There are two test methods of PCB open-short circuit test. One is fixture test, and the other is flying probe test.

Fixture testing is based on the test points on the circuit board to make a fixture with a bed of needles and many thin needles on it. Each needle corresponds to a test point and is pressed to make contact. Then conduct a continuity test or a functional test.

Flying probe test is a rapid movement of several probes at these test points, contact with these test points, and then the instrument measures the results.

Inspection of Rigid Flex PCB Board

Dimension measurement: measure whether the actual dimension of the PCB matches the customer’s original rigid flex circuit design file.

Holes: Check for missing holes, multiple holes, blocked holes, and hole size if matches rigid flex PCB design file.

Circuit: geen kortsluiting, open circuit, blootliggend koper in de geleider, zwevende koperfolie, reparatiedraad, enz.

Silkscreen Printing: The silk screen printing of characters and symbols on the surface of the rigid flex PCB must be clear, and obvious, and the color meets the requirements, without repeated printing, missing printing, multiple printing, position deviation, and misprinting.

Rigid flex PCB warp and twist inspection: According to the IPC-6012 standard, the warp and twist of the rigid flex circuits should be within 0.75%.

Solderability Test: Take part of the rigid flex PCB for actual soldering to check whether the parts can be easily soldered.

Packaging: colorless air bag vacuum packaging, with desiccant inside, tightly packed.