The PCB board industry is surprisingly beating the odds despite the aftermath of COVID-19. According to the newswire, the PCB fabrication will reach up to $108 billion in 2033. These statistics show an unparalleled growth of circuit board companies across the globe.

It won’t be wrong if we say the printed circuit boards are like the nervous system of any electronic device. They provide a reliable way to flow electric signals in an order. Subsequently, a nice PCB design is indispensable to ensure smooth performance in tough conditions.

Early electronic components were manufactured and connected manually using wires in a point-to-point construction. Therefore, this old method had a greater chance of inviting malfunctions. Now due to the latest PCB design software, PCB manufacturers can easily carry out PCB fabrication and PCB assembly process.

What is a PCB?

A PCB board can be flat, flexible, or rigid and has insulating material such as fiberglass or epoxy resin. This functions as the foundation of mounting and connecting electronic components.

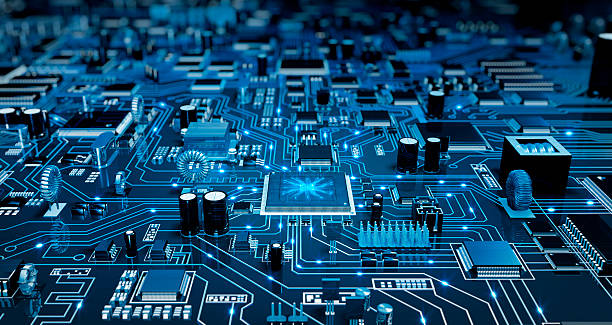

Printed circuit board historically printed with a silkscreen onto a board. Before we were diving into the details let’s take a moment and check out how they look normally. Generally, they have a green appearance with gold or copper dots. In case you wonder where to find PCBs in your daily life?

Everywhere. Starting from your computer your phone to development equipment like:

- A Raspberry Pi

- Your headphones

- USB drive

- Camera

- Speaker

- Calculator or even your car

The Evolution and Development of PCB Technology

Because these circuits were extremely complex repairing one that had been damaged was an unreliable tedious task. Therefore, in 1936 Paul Eisler a genius engineer who worked for a newspaper company recognized the hurdles and invented the concept of printing conducting copper circuits on a non-conductive board.

However, a modern-day PCB board looks like this much more sophisticated tiny, and complex. Modern-day PCB manufacturing starts from a simple copper flat sheet.

Types of PCB

Printed circuit boards come in multiple types serving particular purposes. Here we shall discuss 5 most popular types of circuit boards. Simultaneously, we shall also discuss their major specifications.

Single-Sided PCBs

- Single-side printed circuit boards have a single layer. Similarly, it has a smooth design and is cost-effective.

- In this type of board, PCB board manufacturers mount components on one side. In addition, the copper traces can run only on one side of the board.

- A single PCB board is ideal for electronics where their design and spacing is not a critical factor.

Double-Sided PCBs

- Double-sided printed circuit boards have mounted components on both sides of the board.

- On dual-side PCBs, the copper traces come on both sides. Similarly, they have plated-through hole connections.

- These types of boards are common in complex electronics, for instance, industrial equipment and consumer electronics.

Multi-Layer Circuit Boards

- Multi-layer printed circuit boards as the name suggests consist of more than 2 layers of substrate. These layers have copper traces sandwiched between them.

- Multi-layer PCB boards have high consumption in high-density and high-performance applications.

- We can find such types of circuit boards in smartphones, computers, and advanced electronics. In these electronics, signal integrity plays a crucial role.

Flexible /Flex PCBs

- Flexible PCB technology as obvious from its name is flex in nature. Generally, PCB manufacturers use materials like polyimide in it.

- Such types of boards are easy to bend. Hence, we can fit them into irregular shapes or tight spaces.

- Flex PCBs are ideal for wearable devices, automotive, and medical equipment.

Rigid-Flex/ Flexible PCBs

- Rigid-flex circuit board combines the characteristics of both flexible and rigid boards.

- These boards have rigid and flexible layers combined.

- Rigid-flex printed circuit boards are ideal for applications where we need to maintain some rigidity such as military equipment and aerospace.

These are just a few examples of the many types of PCBs available. Every electronics board has a special role and can be customized during PCB design to meet the specific needs of various industries and electronic devices.

PCB Materials

Everyone knows what a PCB looks like, but not so many people know that at first. This small piece of technology starts with such a large panel. – Yes, we start with this very large panel. Similarly, during this extensive process, we need to select the correct brand. Subsequently, we need the correct thickness to get the perfect PCB at the end.

Let’s have a look! PCB board manufacturers assist in PCB fabrication. They are not raw material providers of circuit boards for instance copper foil or prepreg.

Moreover, all materials are stored by:

- Type

- Total thickness

- Copper thickness

- And brand

These large panels are already composed of copper and FR4. The copper covers the top and the bottom of the panel and inside, sandwiched, is the FR4.

FR4 consists of fiberglass and epoxy resin. This step is at the start of the PCB board creation. Ensuring the inspection of every part is critical. Because it won’t impact the performance of the device in the future. For optimum performance, we need to check the copper and the total thickness of the circuit board.

These days, PCB board manufacturers pay special attention to two factors. These are edge finishing and panel geometry. Therefore, the engineering team carefully selects the ideal manufacturing process. In addition, PCB fabrication also depends a lot on PCB design.

Each Part Number has its own selection of raw materials as well as its own production process, which depends on the quantity.

PCB Board Design

This will be the first time that you’ve ever designed the PCB and you don’t know much about PCB design. I suspect for most of you that’s the case and so there are a couple of important concepts. We shall go through some of the key steps in the design process which essentially begin with schematic capture.

You place your schematic into the layout tool all right. So you’ll do that in CAD what you then do is you get that schematic ready for layout. Netlist basically creates for us a list of all the nodes in the circuit and tells us where all the nodes are connected.

A PCB design is the process of making a printed circuit board layout following a particular layout which should be accommodating with particular electronic devices. Generally, PCB design involves 10 steps which are:

- Component Placement:

- Routing:

- Layer Stackup:

- Signal Integrity:

- Power Distribution:

- Thermal Management:

- Design Rules and Constraints:

- 3D Modeling:

- Testing and Simulation:

- Documentation:

PCB design helps us to deal with our requirement interactions. Similarly, all of our designs have a logical and physical side that needs to be properly managed to create the perfect design.

So, what do PCB design rules do? They allow you to define a system to you know automate the checking of these requirements. Furthermore, PCB design gives you an interface between the logical and physical sides so that you can produce a board. A good design of PCb leads to successful PCB assembly.

How does PCB work?

A PCB board works under following a specialized structure. This structure consists of several electronic components and sophisticated wiring. This design allows a circuit board to communicate and execute tasks. Here are the most common PCB board components that play a crucial role in carrying out all operations:

- Component Mounting:This part consists of several components. The popular components are resistors, capacitors, transistors, integrated circuits (ICs), and connectors.

- Conductive Pathways:A circuit board relies on a network of conductive pathways. These pathways act as electrical wires, providing a path for electrical signals.

- Signal Flow:When we turn on the electrical devices, current flows through the conductive pathways on a circuit board.

- Circuit Functionality:The arrangement of the components during PCB fabrication determines the functionality of the electronic circuit.

- Signal Processing:Components on a circuit board allow electrical signals. This function varies from resistors to capacitors. What’s inside the printed circuit board and how does it work?

We can also find several other pads on the PCB, such as:

- The memory chip

- Wireless chip

- Resistors

- Capacitors

If there are more traces, it will allow more data for smooth and quick operations. Interestingly, these traces are electrically separated and cannot cross each other.

Conclusion

In summary, the PCB board makes it possible for each component available on the device to communicate with the rest of the system efficiently. Therefore, it is best practice to contact an expert in the PCB fabrication industry.

We always recommend hiring a professional PCB manufacturer for PCB fabrication, PCB design, and PCB assembly. Ultimately, it will help you to make reliable electronic parts.