What is Rogers RO4003C, RO4350B material?

Rogers PCB RO4003C, RO4350B material is a high-frequency material type produced by Rogers company.

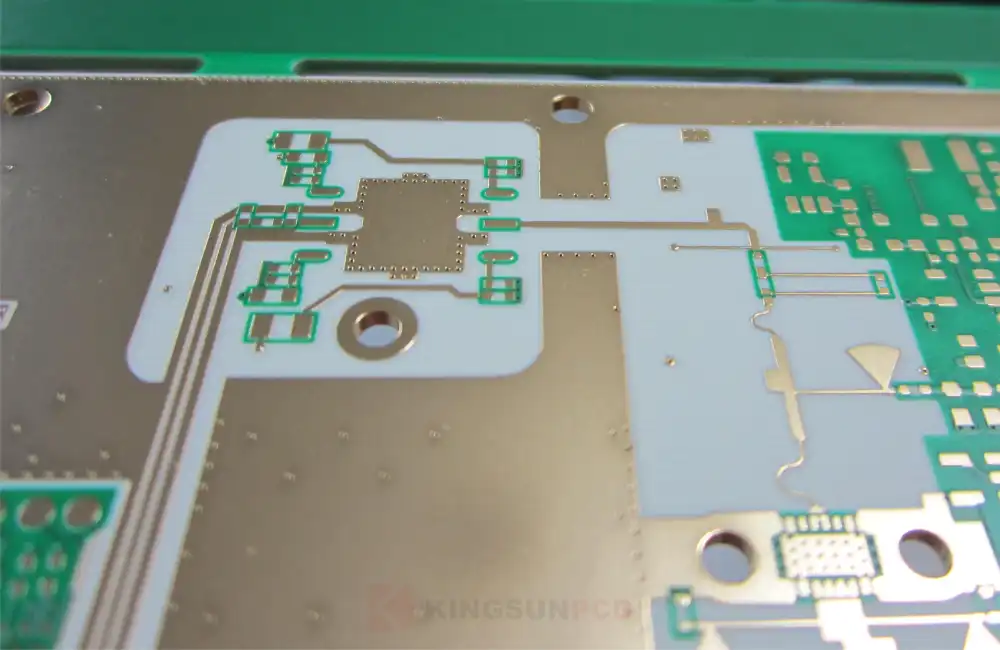

Unlike the traditional FR4 PCB, they don’t have glass fiber in the middle. They use a ceramic base for high-frequency material.

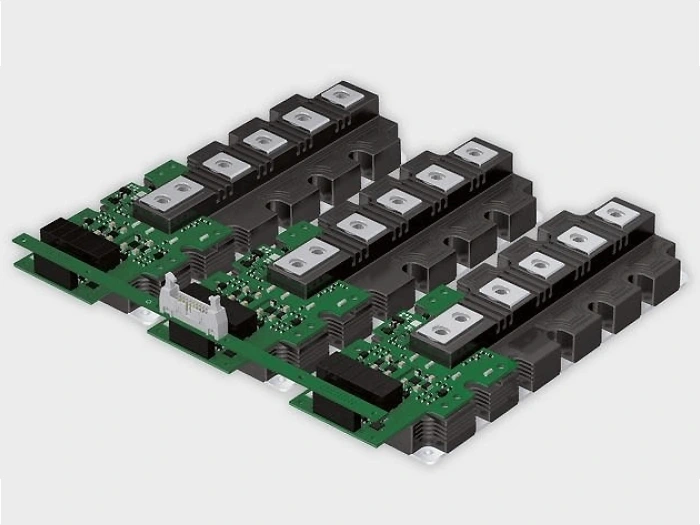

Rogers RO4350B and RO4003C are the most common series materials in the Rogers family. They are used in the manufacture of Rogers PCB as hard and dense material properties. Widely used in high-frequency power distribution and CUP circuit boards, switches, connectors, etc.

RO4350B and RO4003C have superior dielectric constant and temperature stability. The dielectric constant thermal expansion is very consistent with the copper foil. It can be used to improve the deficiencies of PTFE substrate. Suitable for high-speed designs, as well as commercial microwave and RF applications.

It has very low water absorption. So, it can be used in high-humidity environments. This gives high-frequency board industry customers the best materials and resources. It also lets them control product quality.

The Rogers PCB material RO4003C RO4350B contains an epoxy resin core, metal-clad copper, and aluminum elements. They have good size and a low thermal expansion coefficient. This can reduce temperature stress and keep the component stable.

They are most commonly used in RF PCB assembly. This is because they are sensitive to electromagnetic (EM) waves, usually in the radio spectrum. This helps reduce interference from other high-frequency devices. They include radios, TVs, and cell phones.

Rogers PCB materials RO4003C and RO4350B have excellent dielectric integrity. They are designed for use on high-performance RF circuit boards.

The materials have great electrical and thermal stability. They are the ideal choice for harsh environments with extreme temperatures and vibrations.