What is the PCB Manufacturing Process?

The full name of the PCB is the printed circuit board. It is manufactured through a printing process.

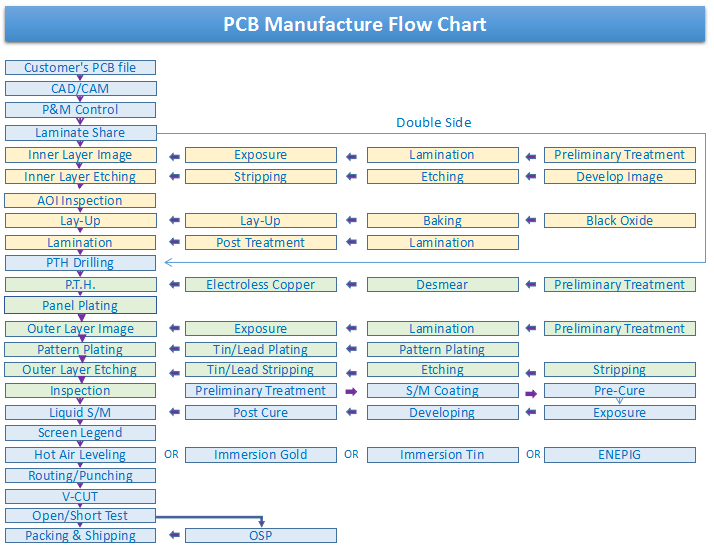

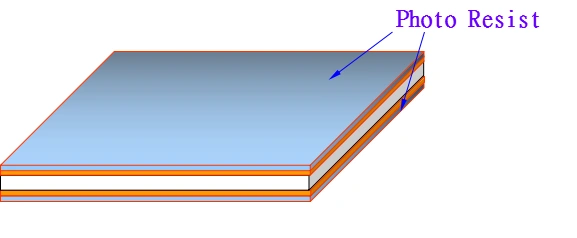

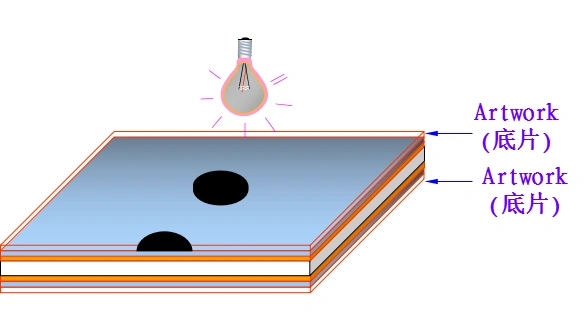

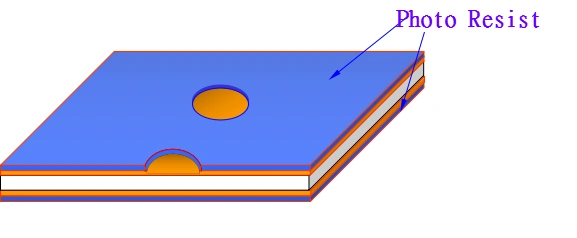

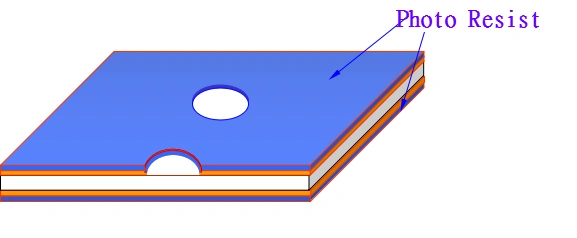

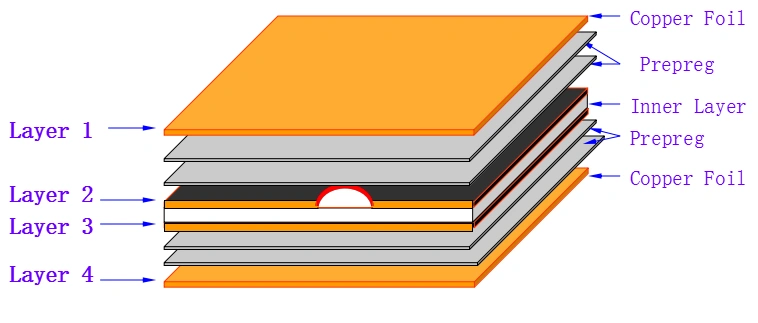

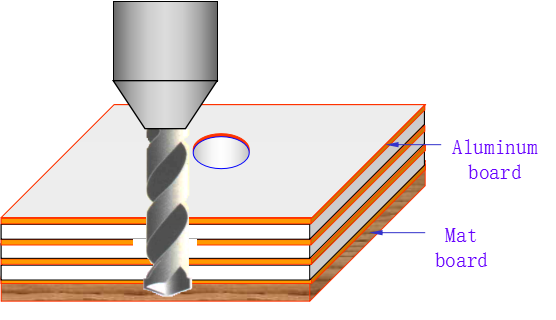

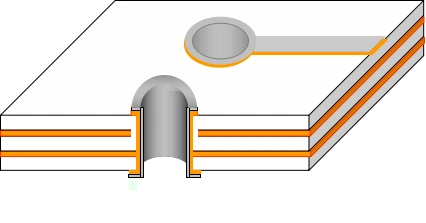

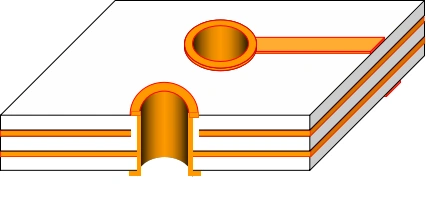

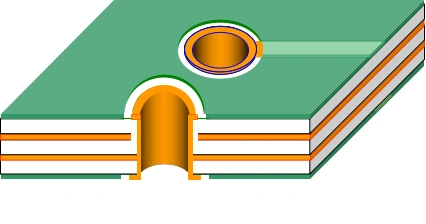

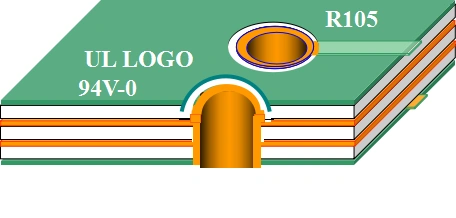

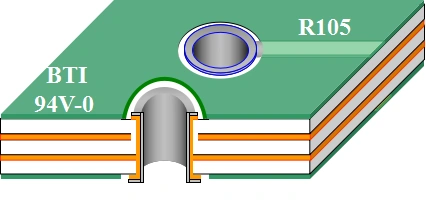

PCB manufacturing techniques involves transferring the PCB graphic onto a copper-clad board. This is done according to the designed circuit pattern.

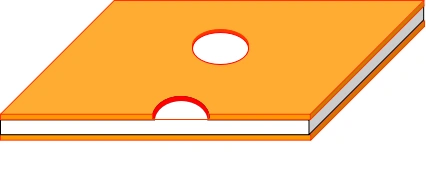

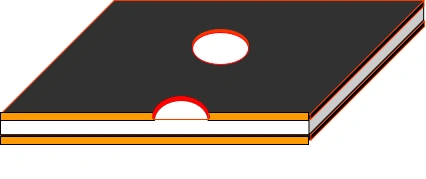

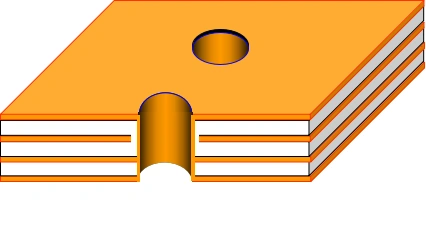

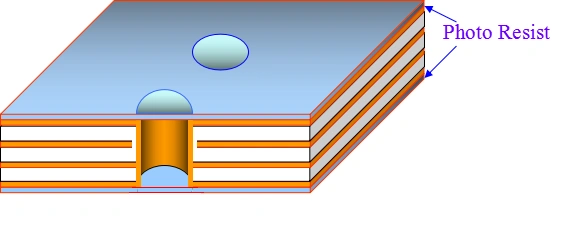

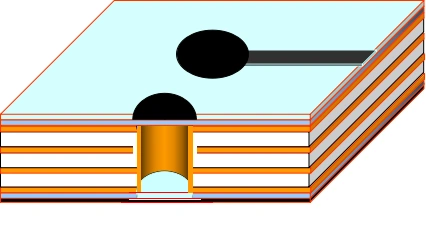

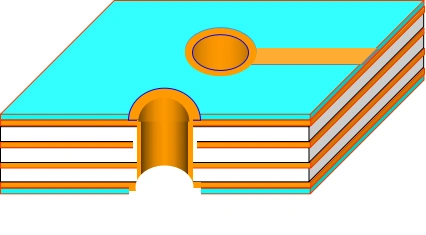

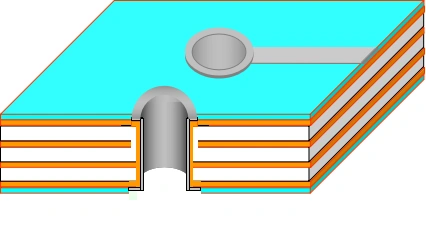

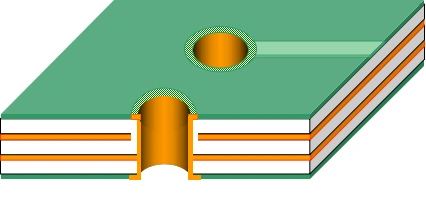

Then, metalize the through holes and print solder mask ink to protect the copper foil and traces.

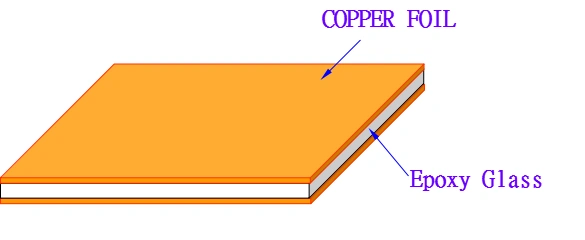

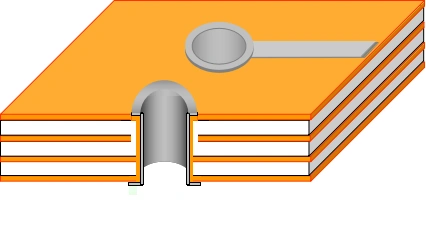

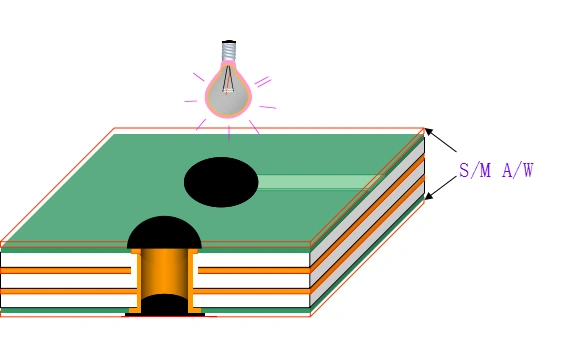

Finally, the exposed pads are surface-treated to form the required circuit board. The circuit board’s raw material is copper-clad laminate. It’s an insulating board with a thin layer of copper foil.

A printed circuit board is the platform for attaching electronic components. It also provides a way for these components to communicate. This creates an electrical conduction pathway.