Countersink Hole

what is a countersink?

Countersink hole is drilled into the circuit board with a flat drill or drill bit but cannot be drilled through.

It is a connection between components that often need to be disassembled and installed.

By embedding the bolt head into the Countersink hole, the problem of the bolt head being easily damaged or falling off is avoided, making the connection point stronger.

Countersink Holes are employed in PCB boards to recess the screw head into the PCB laminate, achieving a clean and flat appearance.

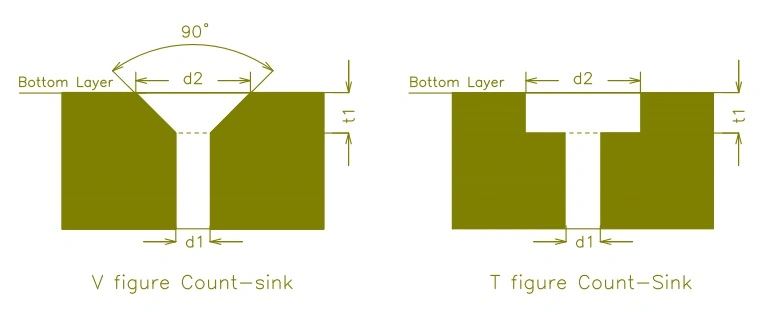

There are typically two types of shapes for countersink holes:

- V-figure Countersink

- T-figure Countersink.

How to drill a countersink hole?

For the first drilling, use a around drill to drill the PCB board and process the via holes and positioning holes.

For the second drilling, a tapered drill tip is used for secondary processing to produce a Countersink hole.

The second drilling uses the same positioning coordinates as the first. After completing the first drilling of the PCB board, do not remove the board and proceed directly to the second drilling.

The drilling and feed speeds of the second drilling are 30% lower than those of the first drilling.

When incorporating countersink design into your board, the following details are essential:

- Determine the drilling side for the countersink hole, such as the Bottom Layer.

- Specify whether the countersink hole should be plated or non-plated.

- Provide the countersink hole diameter (d2).

- Specify the through-hole diameter (d1).

- Indicate the required depth for the countersink hole to sink (t1).

- Specify the angle of the countersink hole, for example, 90 degrees or other.

Applications of countersink hole

Countersink holes, also known as conical holes, are used in various industries for fastening, aerodynamics, woodworking, metalworking, plastic molding, and decorative purposes. Widely used in automobile, machine manufacturing and other fields.

They provide a flush surface for fasteners, improve aerodynamics, prevent wood splitting, and create smooth surfaces in metalworking and plastic molding.

Countersink hole design of the PCB board makes the entire assembly of electronic products smaller and smoother during installation.

Countersink hole size charts

| Countersink Hole Size Charts | ||||

|---|---|---|---|---|

| Thread | Pitch | Drill Size | Countersink Hole | Depth Countersink Hole |

| M2 | 0.4 | 1.7 | 4.0 | 2.5 |

| M2.5 | 0.4 | 2.1 | 4.7 | 3.0 |

| M3 | 0.5 | 2.5 | 6.0 | 3.5 |

| M4 | 0.7 | 3.3 | 7.5 | 5.0 |

| M5 | 0.8 | 4.2 | 9.0 | 6.0 |

| M6 | 1.0 | 5.0 | 10.5 | 7.0 |

| M8 | 1.25 | 6.8 | 13.5 | 9.0 |

| M10 | 1.50 | 8.5 | 16.5 | 11.0 |

| M12 | 1.75 | 10.25 | 18.5 | 13.0 |

| M14 | 2.0 | 12.0 | 21.5 | 15.0 |

| M16 | 2.0 | 14.0 | 24.5 | 17.0 |

| M18 | 2.5 | 15.5 | 29.0 | 19.0 |

| M20 | 2.5 | 17.5 | 30.5 | 21.0 |

The CAM file of countersink hole:

1. Editing of routing layer

It is important to know the depth of the countersink hole. It will be drilled into the layer that needs copper to be cut at the inner and outer layers for NPTH, and whether it affects electrical performance for PTH. Usually, the depth tolerance also needs to be considered when calculating the countersink hole depth.

For example, the NPTH countersink hole needs to be drilled from the top layer to the fourth layer, and then the L1-L4 must be according to the countersink hole without leakage copper and cutting copper to make it at the inner and outer layers. For example, if the hole diameter is 4.5mm, the inner layer does not leak copper with cutting copper of 0.2mm, so the inner hole corresponding to the overall size of the cutting copper should be 4.9mm.

2. Editing of the solder mask layer

If it is NPTH, the welding window shall be opened at least according to the NPTH hole corresponding to the countersink hole.If it is PTH, the welding window shall be opened properly according to the outer layer of the countersink hole. If the customer does not design the mask window, confirming the normal window opening according to the welding pad is necessary.

For example, a 4.5mm NPTH countersink hole be drilled from the top layer; if the normal NPTH hole welding resistance window is larger than the hole with 3mil, then the corresponding countersink hole top layer welding resistance window is 4.5mm+0.15mm=4.65mm.

3. Countersink hole files output notice

The drill hole output must be mirrored when the countersink hole is drilled at the bottom layer.

4. Process instruction

PTH countersink hole is usually done after standard drilling.

NPTH countersink hole is usually placed in front of the milling process.