The process method of blind and buried vias

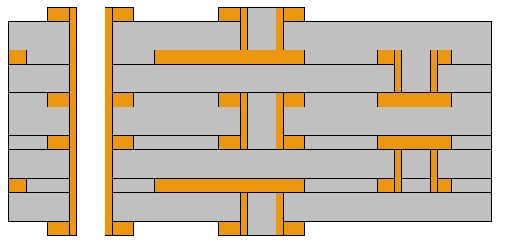

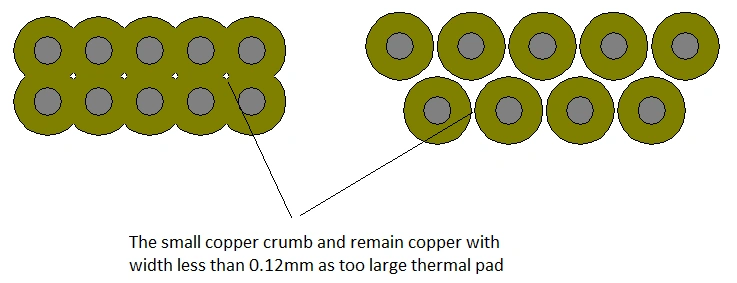

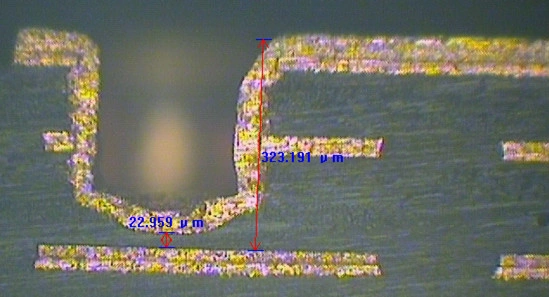

1. Depth Drilling Method

Use mechanical to drill the depth of the blind to achieve the connection between the inner layer and the outside layer. The drawback of this method is its low productivity, as only one piece can be machined at a time. Additionally, the processing is challenging, and reliability is compromised.

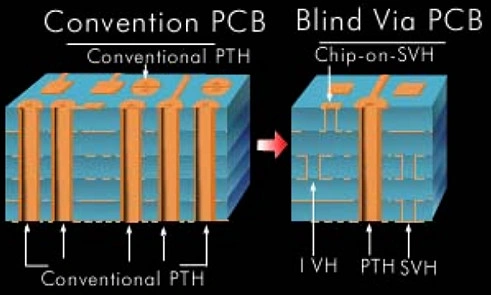

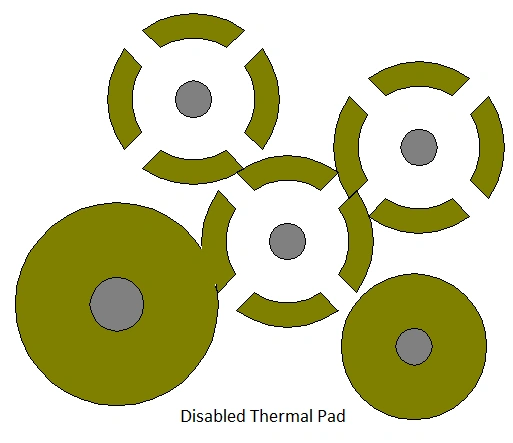

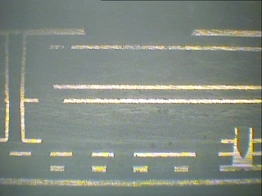

2. Sequential Laminating

Through repetitious pressing, I made out the buried vias, the blind vias, and the through hole successively. The weakness of this method is that it is not easy to control the expansion after repeatedly pressing; the processing is also long. This method can’t make cross-blind and buried vias.

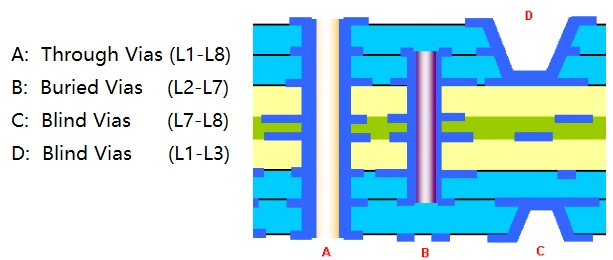

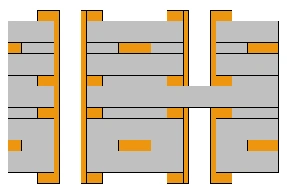

Blind via(L2-L4,L4-L8)

Blind vias(L1-L3)

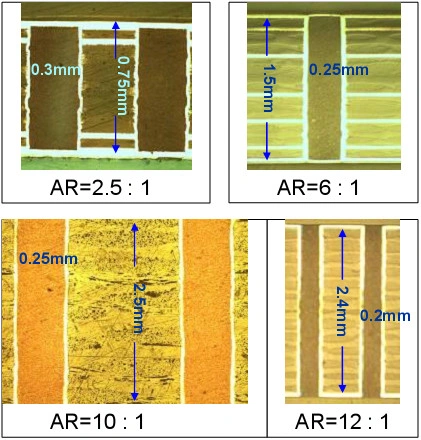

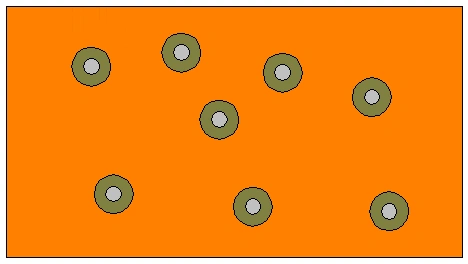

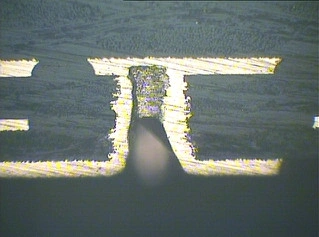

3. HDI Build-Up

The method of laser drilling increases layer by layer for progressive lamination. Disadvantages: high-level equipment requirements, high plating ability, and high cost.