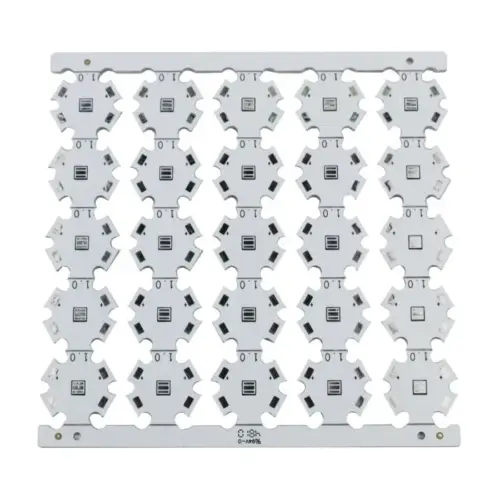

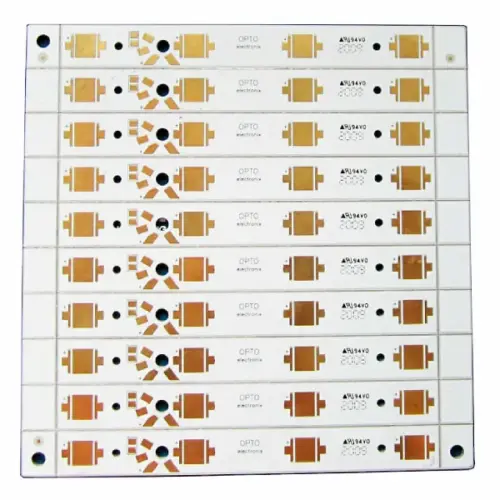

What is MCPCB?

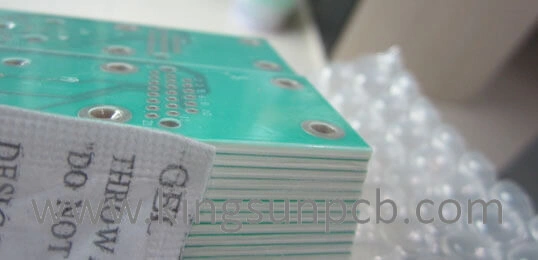

The MCPCB (Metal Core PCB, thermal PCB) is a PCB made of metalcore and copper to laminate, which has good heat dissipation.

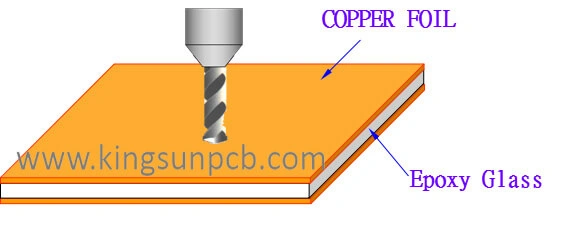

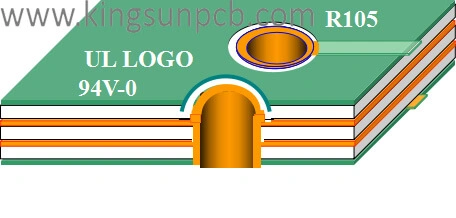

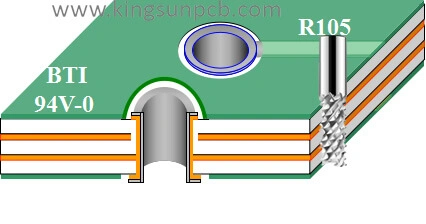

In general, the MCPCB board comprises three layers:

- Copper Foil

- Insulating Layer

- Metal-clad Layer

Metal core printed circuit board (MCPCB) can minimize thermal resistance. This means they have excellent thermal conductivity compared with FR4.

Request MCPCB Quote

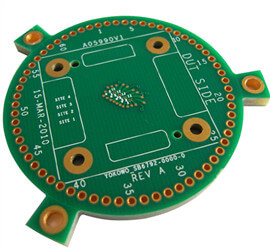

-gallery-770x578-1-500x500.jpg)